Idle-Eze Solves Cam Shaft Idle Problems

By Sam Moore

When upgrading the camshaft of a street vehicle, a difficulty at engine idle may appear where there was none before.

Until recently, the most common remedy for a camshaft-induced poor idle has been for engine builders to drill a hole in each butterfly or throttle plate within the carburetor. But why can the quality of idle be so adversely affected by the installation of a performance or racing camshaft? And why would such customized holes be used to improve the idle? What would be the correct diameter of the holes; how would you gauge that; and what are the consequences if the holes are drilled too large in the butterflies? Perhaps the best question would be: is there a better way to retain idle quality and throttle response within the engine while taking advantage of the extra power provided by a modified camshaft?

Matched to the right components, performance and racing camshafts are impressive in their gains of power. But, due to their increased inherent overlap (the period when the inlet and exhaust valves are open simultaneously), idle quality can suffer because the difference in pressures above and below the carburetor butterflies has been altered. The upper side of the butterflies must attain greater than atmospheric pressure, and the underside must be closer to a vacuum, which creates the signal that activates the carburetor and provides the subsequent flush of fuel-and-air mixture.

With a large-profile camshaft installed, the carburetor is usually deprived of engine vacuum at idle: the insufficient signal is unable to entice the idle circuits to fully cooperate. Often, in an anxious attempt to improve a poor idle, the idle-speed screws are adjusted and as a consequence butterflies opened--opened further than they were originally intended to be in the idle position. This causes the idle-mixture circuits to cease, or partially cease their fuel delivery within the carburetor. Now, idle fuel is being drawn through the line of least resistance, namely the increasingly exposed transfer slots, which are small slots located in the bores of the baseplate that adjoin the butterflies. The chief function of the transfer slots is not to act as idling circuits, but instead to add fuel during the carburetor's transition from the idle-mixture circuits to the main circuits. Therefore the tuning (the positioning) of the butterflies in relation to the transfer slots must be correctly made, or symptoms of disproportion will occur: excessively rich idle, bellowing black smoke, teary eyes, and idle-mixture screws that have been rendered useless.

Years ago, some enterprising engineer realized there were at least two approaches available to him for generating airflow through a carburetor: the traditional method of pressure difference and another of increasing the access area. Recognizing that the larger camshaft generated less vacuum beneath the throttle plates, therefore less pressure differential and consequently less airflow, he decided to obtain his idling air by drilling holes in the carburetor's butterflies--allowing the increased area (the holes) and the available atmospheric pressure above to resolve the problem of poor signal (vacuum). This cleverly adaptive solution allowed engines with modified camshafts to operate at idle as butterflies were returned to their original position and idle-mixture circuits functioned as they were designed. However, given the almost infinite number of engine combinations, how could one decide with any degree of accuracy about the correct drill size? Unfortunately, there was no exact formula, only the educated guess of proportionate size. Further, this sort of change cannot easily be reversed. Once drilled in error the holes can only be plugged--usually less than gracefully.

The Idle-Eze(TM), a new patent-pending concept from Barry Grant's carburetor manufacturing division, Demon Carburetion of Dahlonega, Georgia, provides the simple solution. It's a spring-loaded, needle valve and brass seat assembly located in a threaded hole in the center of the baseplate.

The Idle-Eze is designed to precisely meter an additional source of air to the intake plenum via four milled channels on the top of the baseplate. After setting the butterflies to their correct idle position, any necessary adjustments to the Idle-Eze can be made by screwdriver through the air cleaner stud hole. The new device not only overcomes idling difficulties with performance camshafts but also allows for a smoother transition from off-idle, corrects the potential for hesitation, and comes as standard fitment on all Speed and Mighty Demon carburetors.

Since all Demon carbs (including their predecessor, the Claw) feature four-corner idle-metering circuits, the new Idle-Eze baseplate can be retrospectively fitted to all. The conversion of these early carburetors is fairly straightforward. It involves the removal of the carb from the engine, and removal of the float bowls, the metering blocks and baseplate from the carburetor. To facilitate the adjustment of the new Idle-Eze, a hole needs to be drilled in the bottom of the casting of the carburetor main body via the air cleaner stud hole. Once equipped with the access hole, the new baseplate together with the metering blocks and float bowls are installed on the carburetor. Before placing the carburetor on the engine, adjust the butterflies. With the carb upside down, the butterflies are set such that they expose approximately .020-inch of the transfer slots (the slot will give the appearance of a small square shape). Next, a screwdriver is inserted through the air cleaner stud hole and the Idle-Eze valve closed by rotating it clockwise until it stops. To return it to a baseline setting, open the Idle-Eze valve by one-and-a-half turns and install the carburetor on the engine.

Now, the carburetor can be primed and the engine started. Use a screwdriver through the air cleaner stud hole to control the engine's rpm. Once the rpm is set approximately and the engine is running at normal operating temperature, begin to adjust the idle-mixture screws.

Adjust the screws either in (leaner) or out (richer) until the engine reaches its optimum idle. Make the adjustments in small increments . Once the idle mixture has been set, adjust the Idle-Eze by using a screwdriver through the air cleaner stud hole to reach desired rpm. Once satisfied, install the air cleaner stud and air cleaner and get ready to enjoy your carburetor.

The Demon Idle-Eze, new tuning aid for matching camshafts to carburetors.

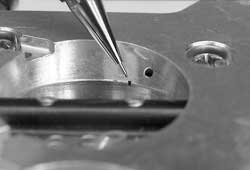

The Idle-Eze assembly as installed in the Demon billet baseplate with accompanying milled slots to provide the necessary source of air to activate the idle-discharge circuits. Air is drawn along the upper milled slots, through the Idle-Eze valve, and exits beneath the butterflies.

Bottom view of baseplate. When converting an existing Demon or Claw carburetor to an Idle-Eze baseplate, remember that the butterfly sizes must not change.

(left) The idle-circuit fuel is discharged through the idle-discharge ports in the baseplate, and the main-circuit fuel via the booster venturii in the main carburetor body. The transfer slots (shown here-exposed by an opening butterfly) are designed to provide a supply of fuel during the transition from idle circuit to main circuit. (right)The perfect positioning for good idle.

Source

Demon Carburetion

Barry Grant Inc.

1450 McDonald Rd.

Dahlonega, GA 30533

(706) 864-8544

www.barrygrant.com

Note: SuperMotors has a business affiliation with Street Thunder Magazine, which provides street rod and automotive content to SuperMotors.

Back to the Issue #1 index.