|

|

L Door to Dash.JPG | Hits: 4901 | Size: 35.37 KB | Posted on: 8/19/04 | Link to this image L Door to Dash.JPG | Hits: 4901 | Size: 35.37 KB | Posted on: 8/19/04 | Link to this image

This is a '94 EB door panel on an '82 door with a '95 vent window and a '95 mirror. The door glass is probably '83. To fit the panel, the armrest brace had to be installed in the correct position (which isn't easy to find) and the vent window had to be changed because the panel covers the front corner. To use '80-86 door glass with a later vent window, remove the plastic spacer inside the track behind the felt glass run. The glass is slightly loose, but it works. That's also a '92-96 PSOM in the instrument cluster, and an '87-91 steering wheel on the '84 tilt column. The cluster bezel is '80-86, but the A/C register is '87-91 passenger-side (turned sideways).  .

|

|

|

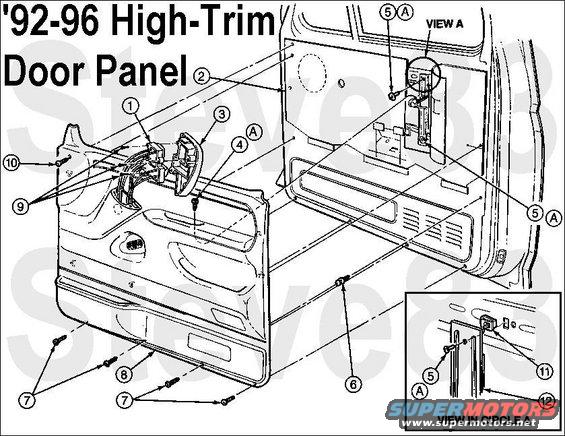

DoorPanel92-96hi.JPG | Hits: 5287 | Size: 82.21 KB | Posted on: 10/17/10 | Link to this image DoorPanel92-96hi.JPG | Hits: 5287 | Size: 82.21 KB | Posted on: 10/17/10 | Link to this image

'92-96 Door Panel, High Trim 1 Window Regulator Control Wiring (Part of 14630) 2 Front Door Trim Shield 237A04 3 Window Regulator Switch Housing 14527 4 Screw (1 Req'd Each Side) 56912-S58 5 Screw and Washer 56914-S58 6 Pushpin (5 Req'd Each Side) N801925-S (Au-Ve-Co AUV-AP12565; possible equivalents include Disco 1575, Dorman 963-010, PDQ 2919T) 7 Screw and Washer Assembly (4 Req'd Each Side) N805121-S303 8 Front Door Trim Panel 23942 9 Screw (3 Req'd Each Side) 55928-S2 10 Screw and Washer (1 Req'd Each Side) N806578-S58 11 Spring Nut N802539-S100 12 Armrest Support 24022 A -- Tighten to 1-2 N-m (9-18 Lb-In) Removal 1. Remove screw(s) retaining the front arm rest pad (24100) to front door trim panel (23942). 2. Remove screw retaining inside door handle (22600). Remove inside door handle. 3. Remove the screw retaining window regulator handle, if equipped. Remove window regulator handle and washer. 4. If equipped with power windows, remove window regulator switch housing (14527). 5. If equipped with power door locks, remove the power door lock switch housing. 6. Remove door lock switch (14028 ), if equipped. 7. Remove outside rear view mirror control (17B676), if equipped. 8. Carefully pry front door trim panel and pushpins away from front door trim shield (237A04), using Windshield and Moulding/Trim Removal Kit. Never pull on front door trim panel to remove pushpins from front door trim shield. Installation 1. Follow removal procedures in reverse order. 2. Tighten screw and washer assembly 1-2 N-m (9-18 lb-in). See also:

|

|

|

Vent Window Removal IF THE IMAGE IS TOO SMALL, click it. The vent window frame is very easy to remove from the door once the door panel is off. Roll the glass all the way down, and remove the 2 phillips screws from the upper front edge of the door frame. (They may be hidden by the upper seal, and on older trucks, they may have 7/32" hex heads.) Remove the 11mm (7/16") bolt from the inner door skin, just rearward of the divider bar and about 6" down from the glass. (Do not remove the 8mm - 5/16" bolt if present.) Pull the rubber glass run down from where the divider meets the top of the door frame & rearward out of the back of the divider and the top of the door. Tilt the vent window frame rearward to remove it from the channel in the door's upper forward edge, and rotate the front of the vent window frame inward 90 degrees. Tilt the frame back and slide it up & out of the door. Work the run out of the divider as it is exposed. Reverse to install. Vent Window Disassembly With the frame out, unlatch & open the vent window, remove the two 5.5mm (7/32") screws from the upper pivot, and remove the 11mm (7/16") crimped nut from the lower pivot bolt. Slide the spring & indexed washer off, and rotate the upper pivot away from the frame. Gently rap the frame & vent window pivot bolt on a solid surface to drive the bolt & window up out of the frame. Catch the nylon washer & limit cam as the bolt clears the frame. Note their order for reassembly. Work the ends of the rubber seal out of their notches in the frame, and peel it out of the channel. On '92-96, remove the 4 staples from the front corner, and remove the penetration shield. Use a steel drift to drive the roll pin out of the latch handle, slide it off its shaft, and collect the button & spring. Tap the steel frame away from the glass to gently bend it (only at its corners) off the glass. Scrape the mounting tape out of the frame channel.  Drill out the rivets for the L-bolt.

|

|

|

DoorWindowSpacer.JPG | Hits: 4086 | Size: 42.07 KB | Posted on: 11/14/08 | Link to this image DoorWindowSpacer.JPG | Hits: 4086 | Size: 42.07 KB | Posted on: 11/14/08 | Link to this image

'87-96 Window Channel Spacer

The divider bar (back of the vent window frame) is deeper in this year range, and the glass is correspondingly shorter front-to-back, so this spacer is installed to take up the difference. Removing it allows the later vent window to be used with earlier main window glass.

For more info, see this:

|

|

|

Door Window Regulators & Vent Note that the regulator (21) is attached by 4 rivets (22) which must be punched & drilled out. But the regulator does NOT need to be removed to access the motor (23). Its 3 bolts (5/16" 6-point head w/integral washer; 12-24x5/8") can be accessed after drilling or holesawing (1/2") the 2 dimples in the inner door skin which mark the 2 concealed screws' locations. 7 & 8 (weatherbelts) can be bought as a 4-piece set as: '80-86 (E0TZ-1021457-A, E0TZ-1021456-A, E0TZ-1021453-A, E0TZ-1021452-A) Fairchild KF2001 or JBG 34386A'87-96 (E9TZ-1521457-A, E9TZ-1521456-A, E7TZ-1521453-A, E7TZ-1521452-A) Generic, or Fairchild KF2005, or JBG 34388AFor motor repair, see these:  .  Door Panel Removal  The unidentified part above 2 & 3 might be the top of the door frame, or it might be the upper seal (20518 ).  .

|

|

|

Two of the 3 window motor bolts are inaccessible while the regulator is riveted to the door skin (I bolted this one in after painting the empty door shell), but Ford conveniently added dimples directly in line with the 2 concealed bolts. Drill them 1/2" for a common 8mm (5/16") deep 1/4"-drive socket to fit in.

See the NEXT few pics...

|

|

|

The bolts are 5/16" (8mm), and a deep socket that size is slightly under 1/2" OD, so use a 1/2" bit to drill the door skin.

See the NEXT & PREVious several pics...

|

|

|

From now on, it will be easy to R&R the motor while the regulator stays in the door.

See the NEXT & PREVious several pics...

|

|

|

Window Motor Repair IF THE IMAGE IS TOO SMALL, click it. After removing the door panel, locate the dimples over the motor bolts, and drill them ~1/2" (just larger than your 5/16" magnetic driver) so the motor can be removed from the door. Remove the cover screw, open the crimps, pop the cover off, clean out the delrin residue, and remove the snap ring & washer from the shaft so the metal gear can be lifted enough to slip the 3 1/4" nuts into the wells of the large plastic gear. See also:  .

|

|

|

The plate that covers the drive gear on this late-model window motor is crimped on, and its paper gasket is very adhesive, so it can take some effort to remove it the first time. Older motors only use the Phillips screw on a flat plate that's easy to remove. Next, remove the snap ring from the center shaft (if equipped, late motors only) and slide the inner metal & outer plastic gears out so the Delrin debris can be cleaned out of the housing, and off the gears. Note that it is NOT necessary to fill the housing with grease, so don't. See also:  .  .  .  See the NEXT & PREVious several pics...

|

|

|

There is a Phillips screw holding the drive plate on, and on later motors like this one, 2 of its corners are staked to the casting. The metal drive gear is also retained by an outside snap ring.

See the NEXT & PREVious several pics...

|

|

|

Later motors like this one have a tiny snap-ring, but it's generally OK to destroy the snap ring since early motors didn't have one at all. The plate holds the gears in.

Dump & brush all the delrin debris out, and do NOT fill the case with grease. Only the center shaft needs a light coat.

GO TO THE NEXT PIC...

|

|

|

Steel nuts will never decay, so this fix will last the life of the motor. Note that it is NOT necessary to fill the housing with grease, so don't. A light film on the shaft, plastic gear teeth, & metal gear O-ring will be enough. Original Delrin pins are available, but they'll break down eventually. See p.35 of this PDF: https://www.henrysautomotivewarehouse.com/2017_web.pdfSee also:  .  .  .

|

|

|

Door weatherbelt differences

The inner (right) is only bent; the outer (left) is bent & relieved.

|

|

|

Door Glass Differences FRONT IS LEFT The divider bar (back of the vent window frame) is deeper for '87-96, and the glass is correspondingly shorter front-to-back. The weatherbelts (inner & outer) are also sized to match the divider bar. For more info, see this:

|

|

|

The panel is very tight against the lower A-pillar, and actually presses into the dash pad (which means the hinges have to be adjusted inward to keep the door against its seal), but they still look & work MUCH better than any older panels. More pockets, better switch location, and just a better look, even though the colors are noticeably different.

.

|

|

|

A wider shot. The spotlight is a Unity from a cop car, the steering column is from an '83 pickup, the steering wheel is an '87, and the seat is an '83 F-150 extended cab captain's chair.

.

|

|

|

This shows the difference in the shapes of the 2 dashes. The pad sticks up because this dash was damaged in the original body when I rolled it. Both A-pillar covers are from an '88 F-150 extended cab.

|

|

|

Door Latch '92 (it was revised in '93 with a rubber cover) IF THE IMAGE IS TOO SMALL, click it. ERROR: the descriptions & PNs for 8-20 are jumbled. In section D, 4 refers to the Z-bent rod below it. 8 on the list is 13 in the diagrams 9 on the list is 17 in the diagrams D2VY-65219A38-B10 on the list is 18 in the diagrams 11 on the list is not shown in the diagrams 12 on the list is 8 in the diagrams 13 on the list is 9 in the diagrams 14 on the list is 16 in the diagrams 15 on the list is 19 in the diagrams 16 on the list is 12 in the diagrams 17 on the list is 14 in the diagrams 18 on the list is 15 in the diagrams 19 on the list is 10 in the diagrams 20 on the list is 11 in the diagrams Door skins: Late '96-97 >8500GVWR (larger keyhole): '95-early '96 (side impact): '80-94: LHF F1TZ1520125A, F2TZ1520125B (FO1301106) ; RHF F1TZ1520124A, F2TZ1520124B (FO1301107) For more info about the lever (F1LY-6321970-A) in Section D, see http://www.supermotors.net/registry/5643/51416-2For pics of a door being installed, see this album: http://www.supermotors.net/registry/2742/66137-4Door Panel Removal  Lock motor  The retainer clip (#11) for the lock cylinder is F58Z-1622023-AA (E9ZZ-6122023-A). Latch Recall  Driver's latch/cable/remote F4TZ-15219A65-APassenger's latch/cable/remote F4TZ-15219A64-A

|

|

|

Door Window Manual Regulator & Inside Handle

Door Panel Removal

|

|

|

The Door Vent Valve (-1520892-) is mounted inside each front door to allow continuous airflow through the cab while the truck is moving forward. Air hitting the w/s flows down through the wiper valance into the cowl to the Right side where it passes forward through the firewall into the engine bay HVAC box, past the blower & evaporator, then rearward through the firewall out the dash through the door panel louvers, through the door shell interior louvers, through this valve, and out the door rear louvers.

|

|

|

DoorWatershield.JPG | Hits: 2016 | Size: 78.68 KB | Posted on: 10/29/12 | Link to this image DoorWatershield.JPG | Hits: 2016 | Size: 78.68 KB | Posted on: 10/29/12 | Link to this image

It's rare to find a factory watershield intact.

|

|

|

Cracks propagating from the vent window tab are probably due to the upper mount for a breakaway mirror putting too much stress on the door skin. Here's my repair:  See the NEXT few pics...

|

|

|

Cracks propagating from the vent window tab are probably due to the upper mount for a breakaway mirror putting too much stress on the door skin. Here's my repair:  See the NEXT & PREVious few pics...

|

|

|

Cracks propagating from the vent window tab are probably due to the upper mount for a breakaway mirror putting too much stress on the door skin.  .  I bent this brace from a flat scrap about the same width as the factory tab so that it hooks behind the mirror nut plate and does NOT fully span the gap to the inner skin. That allows the tension to be adjusted by tightening the screws. See the PREVious few pics...

|

|

|

Door Weight 65lbs

PW/PL, wiring, speaker, main glass, vent window, latch, handles, & hinges

MISSING: mirror, vapor barrier, door panel, side impact beam ('95-96 only)

|

|

|

Lock Cylinder Removal with plastic arm Since this style of plastic lever is known to break, it's safer to slide it off the end of the operating rod than to try to compress its tabs to release the rod. The retainer clip for this lock cylinder is F58Z-1622023-AA (E9ZZ-6122023-A).

|

|

|

Factory THEFT System Switch ('94-95 only) is not really for an "alarm"  .  These are rare, fragile, and probably not in production anywhere at any price. They are ONLY used to deactivate the THEFT system. But it's common for the switch to jam internally and then break off of the lock cylinder, causing false alarms when the door is unlocked with the key instead of the remote.

|

|

|

DoorHandleEarly.jpg | Hits: 483 | Size: 72.94 KB | Posted on: 3/15/19 | Link to this image DoorHandleEarly.jpg | Hits: 483 | Size: 72.94 KB | Posted on: 3/15/19 | Link to this image

Some door handles have an open skirt for the button.

|

|

|

This type of rod keep is used in doors & tailgates.

|

|

|

Door Seal Details The upper seal (20518 ) is available aftermarket ~$20, but I haven't confirmed that those are the same shape as the original formed seals, which were only installed on high-trim trucks.  For pics of a door being installed & aligned, see this album: http://www.supermotors.net/registry/2742/66137-4Door Panel Removal

|

|

|

DoorGsktFiller.JPG | Hits: 2640 | Size: 75.14 KB | Posted on: 12/19/12 | Link to this image DoorGsktFiller.JPG | Hits: 2640 | Size: 75.14 KB | Posted on: 12/19/12 | Link to this image

To rejuvinate collapsed door gaskets, insert foam caulk backer rod. Larger foam will fit, but this is sufficient, and fairly easy to install. I was able to push about 5 feet directly in, and then use needle-nose pliers through the vent holes to pull the rest through. A long wire fed through beforehand would have made pulling the rod in even easier, but eventually the rod will have so much drag that it tears apart. Any leftovers can be used in the doors:  .  .  Immediately after this, the doors should be fully aligned to prevent further damage to the seals. http://www.fourdoorbronco.com/board/showthread.php?6884-Door-AlignmentFinally, apply silicone spray lube &/or teflon dry lube to the gaskets to keep them soft, clean, and silent.

|

|

|

DoorGasketStuff.JPG | Hits: 3004 | Size: 58.42 KB | Posted on: 10/19/11 | Link to this image DoorGasketStuff.JPG | Hits: 3004 | Size: 58.42 KB | Posted on: 10/19/11 | Link to this image

Door Gaskets that have collapsed can be stuffed with caulk saver cord to eliminate wind noise & door rattles. This is MUCH easier to do with the gasket off the truck. Larger foam will fit, but this is sufficient, and fairly easy to install.

Any leftovers can be used in the doors:

Immediately after this, the doors should be fully aligned to prevent further damage to the seals.

http://www.fourdoorbronco.com/board/showthread.php?6884-Door-Alignment

|

|

|

This scrap of caulk-saver rod from the door gasket filler will prevent small pebbles & parts from jamming in the narrow gap, causing dents or rust. The bottom is open to allow water to drain rearward. It can also be used above the rear wheel arch reinforcements, and inside the door seals.  .  .  Note that this '93 door skin does NOT have a side-impact beam ('95-up). It would run along the bottom outer skin about from the finger pointer past the missing paint to the back edge of the door.

|

|

|

Inside Door Latch Handle Repair IF THE IMAGE IS TOO SMALL, click it. After removing the door panel, inspect the skin where the mechanism attaches. If the hinges or latch have been neglected, or if the cable has been greased, excess force needed to open the door will rip the sheet metal where the single bolt attaches the mechanism to the skin. A simple washer under the skin is usually enough to reinforce it, even with severe damage. The U-nut can be used to hold it in-place. The gap at the rear of the mechanism may also be closed, which is frequently mistaken for a stretched cable (which doesn't happen). If the cable is gummy, the latch must be removed from the door to remove & wash the cable in solvent. Bend the tab back so that the handle does not need to be lifted far to release the latch. This also puts the cable down against the door so that the panel's rear pocket lies flat instead of breaking at its front outer corner. See also:

|

|

|

DoorLatchCracks.JPG | Hits: 3911 | Size: 49.25 KB | Posted on: 11/14/08 | Link to this image DoorLatchCracks.JPG | Hits: 3911 | Size: 49.25 KB | Posted on: 11/14/08 | Link to this image

Because of a defect in the inside handle assembly & another in the latch built for cable operation (both recalled), the '92-96 door skin is prone to crack where its single U-nut attaches. A small reinforcement like this will prevent or stop the damage, and a slightly larger one will repair it if the damage is worse.  For '92-96 doors (cable to inside handle), see this recall:  SEE THE PREVious PIC...

|

|

|

Inside Door Handle Reinforcement IF THE IMAGE IS TOO SMALL, click it. This scrap of cold-rolled 1.5" angle iron is the perfect size to make a plate for each door, even though it's probably MUCH larger than necessary. Later, I'll JBWeld it to the door skin to make sure the stress is evenly distributed. See also:  SEE THE NEXT PIC...

|

|

|

This shows why the '92-96 door pocket doesn't sit right in the door panel, and often cracks.

If the bracket warps at the point indicated, and the edges become misaligned, the rear tab will bend forward, and the cable sheath will rise under the armrest brace (vertical galvanized), pushing against the door pocket. Be sure these edges remain aligned as indicated in this TSB:

|

|

|

1992 Bronco body.JPG | Hits: 5672 | Size: 64.42 KB | Posted on: 2/9/07 | Link to this image 1992 Bronco body.JPG | Hits: 5672 | Size: 64.42 KB | Posted on: 2/9/07 | Link to this image

|

|

|

Door Height & Tilt

IF THE IMAGE IS TOO SMALL, click it.

When a door is VERY out-of-alignment, the quickest way to get it back is to remove the fender & strike bolt, loosen all 10 hinge bolts, and use a thin board to hold the door parallel to the rocker while holding it against the cab opening & gasket, and lifting/lowering the board to adjust the door's height. The door's back edge should be 1/16~1/8" from the body, and its top about the same from the drip rail. When it settles into the opening, push the lower hinge HARD rearward against the door while tightening its bolts; then push the upper hinge HARD forward and up while tightening its bolts. That preloads the hinges the way the door will without the board. Ideally, the door should not drop or tilt when the board is removed. Then the position can be finely adjusted so the body line under the door handle PERFECTLY aligns with the cab body line, before re-installing the strike bolt and adjusting it to hold the door flush with the cab.

|

|

|

Worn Hinge Adjustment

IF THE IMAGE IS TOO SMALL, click it.

If the upper hinge wear is minor, it can sometimes be adjusted out by simply loosening the front 2 bolts, and bumping the upper hinge forward to tilt the door back up in the rear into alignment (done with the strike removed). It's much harder to bump either hinge up, or the rear hinge forward - in either case, it's better to bite the bullet and replace both hinges.

|

|

|

The first step is to align the strike bolt so the door bends are perfectly aligned with the body bends when it's fully closed. Striker bolt torque is 24-33lb-ft (33-45Nm). Check vertical alignment against the body lines, and horizontal alignment between the surface of the door & the surface of the body (flushness). Front-to-back alignment (spacing) isn't critical at this point. For door alignment, see this post: http://www.fourdoorbronco.com/board/showthread.php?6884-Door-AlignmentFor pics of another door being installed, see this album: http://www.supermotors.net/registry/2742/66137-4Go to the NEXT pic...

|

|

|

The first step is to align the strike bolt so the door bends are perfectly aligned with the body bends when it's fully closed. Striker bolt torque is 24-33lb-ft (33-45Nm). Check vertical alignment against the body lines, and horizontal alignment between the surface of the door & the surface of the body (flushness). Front-to-back alignment (spacing) isn't critical at this point. For door alignment, see this post: http://www.fourdoorbronco.com/board/showthread.php?6884-Door-AlignmentFor pics of another door being installed, see this album: http://www.supermotors.net/registry/2742/66137-4Go to the NEXT pic...

|

|

|

It's easy to tell that the door is aligned vertically, laterally, and rotationally within the door opening when viewing from this angle. To check its horizontal (fore-aft) position, compare the gaps along the upper A-pillar & the entire B-pillar.

Go to the NEXT pic...

Note the screen in the HVAC fresh-air intake.

|

|

|

A flat board resting on the threshold lip will keep the door aligned with the opening & the drip rail (which is curved). The rear hand can set the door's fore-aft position while the forward hand adjusts & tightens the hinge bolts.

The foam filler between the cowl & fender had separated from its mylar facing, so I rebuilt it using 3M general automotive spray adhesive.

Go to the NEXT pic...

|

|

|

RHF Upper Hinge Differences (Note that upper hinges for the Right door are stamped LS; left-side hinges are stamped RS.) The F-series & Bronco lower hinges are identical (reversible), and did not change from '80-96 (& '97 >8500GVWR). Early upper hinges use an S-spring rod & an indexed roller wheel that must be greased frequently (and turned manually occasionally) to avoid noise. Later hinges use a larger roller & flat band spring with rubber reinforcement, but the band is known to crack. If it does, HELP 38435 is one way to fix it. To install a hinge & align the door, read the other captions in this album.

|

|

|

To make it easy to ID the upper hinges for the doors (the lower hinges are the same), the subcontractor who made them thoughtfully stamped markings into them.

|

|

|

Lower door hinges are identical & interchangeable side-to-side, and for all years '80-96. Upper hinges differ slightly by year (though they're still interchangeable) AND by side. Fortunately, the subcontractor who made them for Ford carefully labelled them for easy identification: LS on right-side hinges, and RS on left-side hinges.

|

|

|

DoorHingeRepair.JPG | Hits: 4149 | Size: 72.65 KB | Posted on: 11/14/08 | Link to this image DoorHingeRepair.JPG | Hits: 4149 | Size: 72.65 KB | Posted on: 11/14/08 | Link to this image

Door Hinge Repair Kits by Dorman/Motormite/HELP!

I prefer to replace the entire hinge with an OE from the JY.

|

|

|

Once the lower door is aligned front & back, check the upper frame's contact with the door seal. If necessary, bend the frame gently to acheive even contact with the door seal. That's my footprint near the sill button hole. I couldn't get a picture of me sitting in the seat with a foot on the door & a hand on the frame, and you probably wouldn't want to see that anyway. :-) For door alignment, see this post: http://www.fourdoorbronco.com/board/showthread.php?6884-Door-AlignmentFor more pics of this door being installed & aligned, see this album: http://www.supermotors.net/registry/2742/66137-4Door Panel Removal  This is the last pic that deals with door alignment.

|

|

|

Rare Door Switch apparently only used in '92-93, for no apparent reason. This truck does not have factory anti-theft or RKE.  .  .

|

|

|

Strike Bolt Differences; all use T50 drive The '89-96 Door bolt shown has a replacement bushing. The bolt is designed to be unscrewed from the safety loop or washer, but after being tightened, the hole sometimes shrinks, making it necessary to apply force to the bolt tip while unscrewing it.  Striker bolt torque is 24-33lb-ft (33-45Nm) for Bronco/F. Dorman 38424 strike sleeve kit

|

|

|

Just ignore all that clunking, rattling, rain-leaking, and wind noise - it's not important. IF THE IMAGE IS TOO SMALL, click it. This is due to HINGE NEGLECT & WEAR, which allows the door to sag, doing this & other damage. So to fix it, START with the hinges, and align the doors. Then keep them clean & lubricated, as the maintenance schedule recommends. Dorman 38424 strike sleeve kitFor door alignment, see this post: http://www.fourdoorbronco.com/board/showthread.php?6884-Door-AlignmentFor pics of another door being installed, see this album: http://www.supermotors.net/registry/2742/66137-4

|

|

|

After any hinge adjustment or replacement, the courtesy light switches must be reset, but it's usually not necessary to remove them as I have. This may also be necessary if the hinges are worn out, but simply resetting the switches won't fix the hinges - they have to be replaced, or the dome light will stay on when the switches get maladjusted again by the worn hinges. Usually, the switches can be reset by spraying on some penetrating oil & then simply pulling the black plunger STRAIGHT out with pliers. Don't grab hard enough to break the plunger head, and don't pull sideways or twist. There's only a slight difference in these door switches. On the early style, the connector (black pointer) actually moves when the pin is pushed, exposing the switch terminals. On the late style (Motorcraft SW6345, Standard DS278T), the switch is fully enclosed. The nut (gray) is 9/16 for both. The brass sleeve (yellow) is adjustable for door alignment. See the NEXT pic...

|

|

|

To reset the switch if it has been removed from the cowl, mount the nut (gray) solidly.

See the NEXT pic...

|

|

|

Spray penetrating oil between the nut & the brass sleeve.

See the NEXT pic...

|

|

|

If the switch is still installed, pulling the black pin PERFECTLY STRAIGHT out with firm smooth force usually achieves this effect. But if the sleeve is seized, simply unscrew the switch and remove its connector. (Don't let the connector slip back into the cowl, especially on the driver's side of '92-97 trucks.) For uninstalled switches, gently tap on the connector to slide the brass sleeve as far out of the nut as it will go.

See the NEXT pic...

|

|

|

The brass sleeve (yellow) is fully exposed, and simply closing the door on it will adjust it correctly. If the hinges are worn out, the switch will lose its adjustment. Late style courtesy switch

|

|

|

'87-91 Power Windows & Locks

|

|

|

PowerWindow95EVTM.jpg | Hits: 10902 | Size: 33.03 KB | Posted on: 12/4/03 | Link to this image PowerWindow95EVTM.jpg | Hits: 10902 | Size: 33.03 KB | Posted on: 12/4/03 | Link to this image

95 EVTM Power Windows IF THE IMAGE IS TOO SMALL, click it. '80-97 similar. The notation for the R window switch is inaccurate: the switch actually provides a CONTINUOUS ground to both motor wires, and momentarily switches one hot to drive the motor. The one that gets switched determines the motor's direction. For more info on tailgate operation, see: http://www.supermotors.net/vehicles/registry/2742/12689

|

|

|

F-series Power Window Circuit

IF THE IMAGE IS TOO SMALL, click it.

The door window circuit is a common (Ford) polarity-reversing circuit with 1 switch for the left motor & 2 switches for the right. The switches share power feed through the ignition switch (key-on only). On Broncos, this feed is also used for the tailgate window motor's dash switch. For the left window, the left (driver's) switch normally holds both motor wires to ground. When operated, it sends one of the wires hot, powering the motor. When operated the other way, the polarity is reversed, reversing the motor's direction. For the right window, the left (driver's) switch normally holds both motor wires to ground, and the right (passenger's) switch normally holds the motor wires to the driver's switch wires. When either is operated, it sends one of the wires hot, powering the motor. When operated the other way, the polarity is reversed, reversing the motor's direction. Neither switch is a "master" because neither will work if the other is in the opposite position. But both must make contact internally when NOT in-use for the other to work.

See also:

.

|

|

|

'80-96 F-series/Bronco Window Circuit IF THE IMAGE IS TOO SMALL, click it. Where this shows the Left switch as one, there are actually 2 independent switches on the driver's door. The door window circuit is a common (Ford) polarity-reversing circuit with 1 switch for the left motor & 2 switches for the right. The switches share power feed through the ignition switch (key-on only). On Broncos, this feed is also used for the tailgate window motor's dash switch. For the left window, the left (driver's) switch normally holds both motor wires to ground. When operated, it sends one of the wires hot, powering the motor. When operated the other way, the polarity is reversed, reversing the motor's direction. For the right window, the left (driver's) switch normally holds both motor wires to ground, and the right (passenger's) switch normally holds the motor wires to the driver's switch wires. When either is operated, it sends one of the wires hot, powering the motor. When operated the other way, the polarity is reversed, reversing the motor's direction. Neither switch is a "master" because neither will work if the other is in the opposite position. But both must make contact internally when NOT in-use for the other to work. See also:  .

|

|

|

SOLD Power Door Harnesses for '80-86 door panels ('87-91 similar)

Non-power panels are pre-marked at the factory to be cut for power switches. Non-power dash wiring includes power connectors for center harness. Doors & cowls are pre-marked for holes to be cut for rubber boots.

Note that passenger harness needs lock motor connector. Driver's harness includes connector, but it must be spliced on at the correct length.

Additional switches & bezels available.

|

|

|

Door wiring boots changed at some point; possibly '94. The newer design is larger at both ends, the corrugated tube is oblong, and is slightly shorter overall. The door end lacks any tabs for taping the wiring harness on.

|

|

|

'93 Bronco XLT Door Wiring

IF THE IMAGE IS TOO SMALL, click it.

|

|

|

One-Touch Window Module Wiring IF THE IMAGE IS TOO SMALL, click it. These modules can be found in most Crown Vics/MGMs/LTCs up to ~'96, and many Taurus/Sables and T-Bird/Cougars of the same era. The module is about 1x2x3", usually in a blue or black case with a black connector in the driver's door. But many Ford modules are the same size & shape, with the same connector, so be careful. The most-common wire colors are indicated on the L, but others are possible. The colors indicated on the R side are for adding the modules to '80-96 F-series & Bronco doors. This feature can be added to almost any reversible DC motor, like power windows, the Bronco tailgate window, power antenna, and even power seats. It'll also work on many other circuits to hold a hot feed for about 10sec after a 0.1-0.4sec hot pulse. The module self-cancels if the current draw exceeds some preset limit, which is how it knows to stop when the window hits the end of its travel, or an obstruction. SEE THE NEXT SEVERAL PICS...  .  .  .

|

|

|

To make the modules work for 1-touch up AND down, gang 2 modules as shown. With the modules back-to-back, the 3 middle wires on each module go straight across to the other 3 middle wires. Then the reds go to the motor wires, & the blacks pair up.  .  .  .

|

|

|

This is the right door harness from a '93 Bronco, but the procedure is the same for almost any reversible 12VDC motor. Cut the wires between the motor & the nearest control switch (R/Y and Y/R in this case). Connect a module's #1 (R) wire to one of the motor wires. Connect that module's #2 (Wh/Bk) wire and the other module's #4 (Y) wire to the harness side of the motor wire (from the switch). Connect the other module's 1,2,&4 wires likewise to the other motor wire. Splice both modules' #3 (Y/LG) wires into the vehicle power circuit (LB/Bk), and both modules' #5 (Bk) wires into the vehicle ground circuit (Bk).  .  .  .  Since this truck's door is normally only grounded through its hinges, I added a ground wire. There is also other additional wiring & modification for RKE, signal mirrors, under-mirror cornering/off-roading lights, & puddle lamps.

|

|

|

1-Touch Up & Down on the driver's door harness from a '93 Bronco XLT

1. This mod requires two common Ford 1-touch modules with pigtail connectors. I zip-tied these together face-to-face and twisted the wires together that will be connected. Then I opened the harness where I'll be splicing.

2. Cut the motor wires and connect them to the modules' red wires. Then connect each cut harness wire to the Bk/Wh from the same module as the R wire is connected to. In this case, one module is connected to the door's Y wires; the other to the doors Bk/Wh wires.

3. Splice the ground & power wires from both modules to the door's Bk & LB/Bk, respectively. I also chose to add a new door ground wire (white pointers).

4. Tape up the splices & reattach any hangers.

|

|

|

Always-On Power Window Circuit IF THE IMAGE IS TOO SMALL, click it. After a lot of head-scratching as to why NO factory builds vehicles this way, and only coming up with a worry-spot, I decided to modify my body donor's wiring harness for always-on power windows. ( Here's why!!!) Since the harness was already out, it was really easy, but it wouldn't be much more difficult (on '87-96) with it installed. Just pull the knee bolster, pull the 2 fuse panel screws, and work it out for access to the front & back.  1. This is a '93 Bronco panel, so the PW hot supply is the top of position 14. This terminal needs to be isolated from its key-on supply, and then connected to an always-on supply. 2. From the back, the buss bar is visible feeding 4 of the 5 terminals on this row. Fortunately, the target is the last one, so it will be easy to isolate. If it was in the middle, a new jumper would have to be added from the original supply wire to the cut end. 3. While holding tension from the back, release the lock for each terminal on the front, and pull the buss bar out of the fuse block. 4. I was able to break this off by hand, but regular wire cutting pliers are easier. Trim away the joiner section and use picks to UNcrimp the single terminal. 5. The shortened buss bar can go back in, leaving the target socket empty. 6. Considering the relatively high current draw of the PW circuit (as much as 20A, based on the factory circuit breaker rating), I selected the hot feed coming in from PDB MAXI fuse L (50A) as being suitable. It feeds the PowerPoint socket in position #13 through this heavy Bk/Or wire. 7. The Bk/Or wire comes into the fuse panel at the unused #5 position, feeds the buss bar going to position #9, then runs on a heavy jumper wire up to position #13. Pull the jumper out of the harness to splice the #14 terminal on. 8. It's probably not necessary to remove the #13 terminal, but it might make it easier to work with. Fold the wire, ring & slice the insulation on each side of the fold, strip it, insert the fold into the opened crimp of the target terminal, and solder it. Re-crimping it isn't secure enough, and 2 layers of this heavy wire would be too much for this terminal's crimp anyway. Solder will hold forever. 9. Reinstall the terminals & fuses, and make a note in the owner's manual so you (& any future owner) can remember this mod. This mod also makes the 1-touch mod more functional, since it can be connected to a remote system.  See also:

|

|

|

DoorSwitch87-96.JPG | Hits: 4010 | Size: 25.46 KB | Posted on: 10/24/10 | Link to this image DoorSwitch87-96.JPG | Hits: 4010 | Size: 25.46 KB | Posted on: 10/24/10 | Link to this image

'87-96 Door Lock & Window Switch Pin 1 is Normally Closed (NC) to pin 2. Pin 4 is Normally Closed (NC) to pin 3. When the rocker is depressed toward pin 1, it opens from 2 & closes to 5. When the rocker is depressed toward pin 4, it opens from 3 & closes to 5. The index peg (lower L of the diagram) is: - L-shaped for Left lock switches - U-shaped for Right lock switches - round for window switches '92-96 Window Switch (all locations) Motorcraft SW7062'92-96 Lock Switch (driver/red key) Wells SW6493, Airtex 1S9028; (passenger/black key) Wells SW6492, Standard PDS-134

|

|

|

Power Window/Lock driver's connector '92-96 WITHOUT factory RKE.

Note the L-shaped hole for the index pin on the Left lock switch above position 5. The lock switch for the Right door has a U-shaped index pin. All window switches have a round pin, whose holes are visible below positions 7 & 9.

|

|

|

Door Locks for '92-96 2-door trucks WITHOUT factory RKE.

IF THE IMAGE IS TOO SMALL, click it.

'80-91 similar

|

|

|

Door lock circuit from the '93 EVTM. All '80-96 (& '97 >8500GVWR) 2-door trucks WITHOUT factory RKE ('94-97 only) are similar.

Note that the lock motors are wired in simple parallel. 4-door trucks simply have 2 more lock motors in parallel, but several more connectors.

|

|

|

LockCircuitRKE.JPG | Hits: 5863 | Size: 80.09 KB | Posted on: 12/3/11 | Link to this image LockCircuitRKE.JPG | Hits: 5863 | Size: 80.09 KB | Posted on: 12/3/11 | Link to this image

Power Lock & Aftermarket RKE Circuit

The door lock circuit WITHOUT factory RKE is a common (Ford) polarity-reversing circuit with 2 switches. The switches share the power feed from the battery (always hot). The left (driver's) switch normally holds both motor wires to ground, and the right (passenger's) switch normally holds the motor wires to the left switch wires. When either is operated, it sends one of the wires hot, powering the motors. When operated the other way, the polarity is reversed, reversing the motors' direction. Neither switch is a "master" because neither will work if the other is in the opposite position OR unplugged. Note that the driver's lock motor is NOT connected to the driver's lock switch.

To add relays or switches to the common Ford power lock circuit (like an aftermarket remote keyless entry system), the power (Bk/Wh) is spliced, but the lock & unlock wires must be cut in ONE of the locations indicated by a dashed line. The Bk/Wh wire is not cut.

Uplus = unlock positive

UC = unlock common

Lplus = lock positive

LC = lock common

Obviously, the new ground can be attached to any reliable ground point; not strictly where indicated. But the new power splice should be on the Bk/Wh circuit so it shares the factory circuit breaker, and has constant power.

Any number of switches or relays can be added, but each one must be CUT into the lock & unlock circuits as indicated. And a long series of switches makes for a poor circuit which can be very difficult to diagnose.

Factory RKE (optional '94-up) uses a ground-trigger circuit which can be simply spliced.

|

|

|

Combined RKE Wiring IF THE IMAGE IS TOO SMALL, click it. This diagram is NOT specific to, OR correct for, any year or model, but most of the connector numbers are for a '96 Bronco. This combined diagram includes ALL inputs & outputs for an imaginary vehicle with every available circuit used (plus a few minor additions that Ford never offered). I combined them because every feature of the RKE system is present in every RKE module, regardless what vehicle that module was originally installed in, or how few features that vehicle originally used. So everything shown here can be added (with relatively little effort) to any vehicle with this RKE module. RKE became an option in '94 F-series/Broncos, and the module is immediately forward of the dash pocket beside the steering column. Theft was available in '94-95 only in trucks with RKE, and that module is above the dash register to the R of the instrument cluster. This module can be added to almost any vehicle, utilizing as FEW features as necessary. IOW: it's not necessary to have PL or RKE to have BatterySaver or IlluminatedEntry. Adding the COMPLETE system to a vehicle NOT originally equipped is VERY labor-intensive since many circuits must be modified, isolated, extended, or added. Connectors must also be repinned or added. Most of the wiring harnesses must be removed from the vehicle to do the work, so it's not a shade-tree job, and even for an experienced electrician, it takes many hours. So the option of adding only certain features makes this much more enticing.  For vehicles with more doors, extra lock motors must ultimately be connected between splices 304 & 306; extra lock switches between splices 301, 302, & ground; extra courtesy switches between splices 212 & 251; extra handle switches between S323 & ground. A KE pad may be added in parallel to the one shown, but a fault in one would interfere with the other, as would simultaneous use. SYSTEM FEATURES Illuminated Entry When a door handle is operated or any keyless entry pad button is pressed (except 7 & 9 to trigger LOCK) or any remote button (except LOCK) is pressed, the illuminated entry circuit (all courtesy lights) & keypad backlight are powered for approximately 25 sec. The feature is deactivated if the key is in RUN or ACC. Illuminated Entry activation also enables the Battery Saver power. Battery Saver Power is disconnected from this circuit AND illuminated entry approximately 45min after the key is turned OFF, even if a door is left open. Power is restored to battery saver when the key is turned to RUN or ACC, a door or the trunk is opened, a door handle is operated, a KE pad button is pressed, or a remote button is pressed. Power is restored to illuminated entry as described above. (From what I've observed, circuit 464 Bk/Pk at C242-20 behaves as if it's merely an extension of the Battery Saver circuit, but I haven't examined the PC board to confirm that.) AutoLock The module can automatically lock all doors when ALL of these conditions are met: 1) feature is active within the RKE module memory 2) all doors are closed (circuit 627 Bk/Or is not grounded) 3) key in RUN (circuit 182 Br/Wh is powered) 4) driver's seat occupied (circuit 177 W grounded) 5) backup lights are on (shifter passes through Reverse position; circuit 140 Bk/Pk is powered) To switch the feature off or on, enter the permanent code, within 5sec hold 7/8, within 5sec more press & release 3/4, release 7/8. Any time battery voltage is disconnected and reconnected, the autolock feature will be activated. Attempting to start a vehicle with a weak battery may also activate the autolock feature. KEYPAD Keypad is used to enter codes & trigger features of the system. The factory code is printed on the module label, on a label in the trunk, and on the card provided with the owner's manual. One user-set code may also be programmed or erased. Any sequence of buttons must occur within 5sec of the previous button or the system will revert to secured. The only exception is the lock-all command (7/8 plus 9/0) which works without any previous code and also arms THEFT (if present). All other commands must follow the permanent or user entry code. When a code is entered correctly, the driver's door unlocks and THEFT (if present) is disarmed. To add or erase a personal code, press 1/2 within 5sec (followed by a personal code to add, or not to erase). To unlock all others, press 3/4 within 5sec. To trigger the trunk release (if equipped), press 5/6 within 5sec. To change AutoLock, hold 7/8 while pressing 3/4. There is no published function assigned to the 9/0 button. REMOTE FEATURES Remote is powered by two 2016 batteries and typically operates up to 33feet from the vehicle. The system can be programmed to recognize up to 4 remotes and will output on discrete circuits to a seat/mirror memory module for the first 2. Other than the #1 & #2 memory outputs, the RKE module does not distinguish between the remotes which it has been programmed to recognize. To program remotes, follow the procedure in the TSB linked below.  Remote Buttons Press LOCK to lock all doors & arm THEFT (if present). To confirm LOCK, press LOCK again to hear the horn beep and see the parking lights flash. To cause the horn & lights to continue for approximately 2:45 and trigger illuminated entry, press PANIC. To cancel PANIC, press PANIC on the same remote, or turn the key to RUN. To unlock the driver's door and disarm/reset THEFT (if present), press UNLOCK; to unlock all, press UNLOCK again within 5sec. Pressing TRUNK causes the RKE module to pulse the trunk release solenoid hot for ~1/2sec. Pressing UNLOCK on the first programmed remote (thus called REMOTE 1) also causes MEMORY OUTPUT 1 to be grounded momentarily; remote 2 UNLOCK triggers MEMORY OUTPUT 2; other remotes have no effect on memory outputs. NON-STANDARD WIRING for '94-96 Broncos & '94-96 ('97 >8500GVWR) F-series shown on the diagram above: - bumper compartment lights - puddle lights - lock cylinder lights - cargo reverse relay (55 Bk/Pk should go to S305) - t/g courtesy switch - seat switch - trunk lamp - trunk release - seat memory - KE switch (keypad) - THEFT was only available in '94-95 - overhead console & vanity mirrors (dual visors) were optional, but common on trucks with RKE - stealth switch When in STEALTH position, this switch allows the driver's door to be opened without triggering illuminated entry. All other features including THEFT are unaltered, so the horn will sound if armed. Opening the t/g with the added courtesy switch while THEFT is active will also trigger the horn.  See also:  .  .  .

|

|

|

'94-95 F-series/Bronco THEFT System IF THE IMAGE IS TOO SMALL, click it. When tripped, the module beeps the horn, flashes the headlights & parking lights, and disables cranking. To reset, either unlock a CLOSED door from outside with the key (NOT the remote), or wait ~90 seconds. This system was offered in trucks ONLY with RKE. But because it's so simple to defeat, it was deleted in '96 and replaced with PATS a few years later. See also:  .  .  .  .  .  .  .  www.bbbind.com/tsb-wiring-diagrams-database/ ---------------------------------------------- DESCRIPTION AND OPERATION The anti-theft protection system operating sequences are designed to be passive; therefore, the system can be armed or disarmed when following normal vehicle exit and entry procedures. The anti-theft protection system provides two types of vehicle protection. The first is designed to provide the vehicle with protection from unauthorized entry into the passenger compartment and engine compartment opening ( hood (16612)) (Econoline only). The second monitors the status of the ignition key lock cylinder. The system is controlled by an anti-theft control (19A366). When armed, unauthorized entry into the vehicle is detected by courtesy lamp switches (13713) (located in the passenger compartment door jambs), and a hood switch (located on the right cowl surface) (Econoline only). In addition, the system is triggered if the ignition switch lock cylinder (11582) is forcibly removed from the steering column. NOTE: The system immediately monitors the ignition switch lock cylinder upon removal of the key from the ignition. It is not necessary to arm the system for monitoring the ignition switch lock cylinder. Once triggered, the system flashes the low beam headlamps, the parking lamps (13201), the anti-theft indicator, and pulses the horn. In addition, the starter circuit is disabled to prevent starting the vehicle until the system is disarmed. Components The system consists of the following components: - Anti-theft control module - Anti-theft warning lamp - Door key disarm switches (Econoline: driver, RH front and rear doors; F-Series and Bronco: driver and passenger doors) - Hood tamper detection switch (Econoline only) - Remote entry module transmitter - Ignition key lock cylinder sensor The following components already exist on the vehicle and are also used in the anti-theft system: - Power door lock switches - Courtesy lamp switches (Econoline: driver, RH front side and rear doors; F-Series: driver and passenger doors) - Horn relay - Low beam headlamps - Parking lamps - Starter relay Arming the System The system will be armed by the remote entry transmitter when the following input sequence is followed: 1. Turn off ignition switch and remove key. NOTE: At this point the anti-theft system automatically monitors the ignition key lock cylinder. If the lock cylinder is forcibly removed, the system will activate for 3 minutes. To arm the system, follow remaining steps. 2. Close all doors (unlocked). 3. Press the LOCK button on a transmitter to lock doors. anti-theft warning lamp will turn on. 4. Wait approximately 30 seconds for the anti-theft warning lamp to turn off. The system will also be armed when the following input sequence is followed: 1. Turn off ignition switch lock cylinder and remove key. 2. Open a door. anti-theft protection warning lamp will flash. 3. Lock doors with power door lock switches (14028 ). anti-theft warning lamp will turn on. 4. Close all doors. 5. Wait approximately 30 seconds for the anti-theft warning lamp to turn off. Opening the driver, RH front side or rear doors or opening the hood will trigger the system after the anti-theft protection is armed. Disarming an Untriggered System The system can be disarmed by performing one of the following procedures. - Unlock front door or rear door (Econoline only) with a key. - Unlock front door (20124) by pressing the UNLOCK button of a remote entry transmitter. - If remaining in the vehicle, turn ignition switch to ON or ACC. The rear door of Bronco is not tied in with the Anti-Theft System. Using the key on the rear door will not disarm the theft system. Triggering the System The armed system will be triggered if either of the following steps is taken. - Any door is opened without using a key or a remote entry transmitter to unlock the door first. - Hood is opened (Econoline). Opening the rear door on Bronco will not trigger the system. Disarming a Triggered System Performing either of the following steps will disarm the triggered system. - Driver, RH front or rear door is unlocked with a key. - Rear door of Econoline is unlocked with a key. - Driver's door is unlocked by pressing the UNLOCK button of a remote entry transmitter. Within two to three minutes after the system has been triggered, the horns and exterior lamps will shut off automatically. The system will then reset to an armed state and will trigger again if another intrusion occurs. The vehicle's starter circuit will remain disabled until the system is disarmed. Activating the PANIC Alarm Press the PANIC button of a remote keyless transmitter. The exterior lights and horn will flash for approximately four minutes or until: 1. the PANIC button is pressed again, or 2. the ignition switch lock cylinder is turned on. On F-Series and Bronco, the panic feature is controlled with the remote keyless entry module and is completely independent of the anti-theft system. Refer to «Section 01-14B» for description of the electronic door lock control system. For panic features, the Econoline uses the anti-theft module to sound the horn and flash the lights.

|

|

|

Possible Keyless Entry Pad Locations for '80-96 truck doors

|

|

|

This is the location I selected for my Keyless Entry keypad, but there are many other possibilities.

See the NEXT several pics...

|

|

|

I carefully cut & shaped the hole with a 4.5" grinder and Dremel.

|

|

|

After painting the cut edges & allowing it to dry, I installed the pad just as it was designed to be, with a thin film of silicone grease on its foam gasket to prevent it from adhering to the fresh paint.

|

|

|

It almost looks like it belongs there!

.  .  .

|

|

|

Sill Button Clip on door latch

|

|

|

Lock Motor Differences

IF THE IMAGE IS TOO SMALL, click it.

The early lock motors are prone to water intrusion; both in the motor itself, and in the spiral BB mechanism, causing poor performance, high current draw, & eventual failure. They were used in F-series/Bronco FRONT doors until '91, and crew-cab REAR doors until '97.

But by changing the connector & the mounting bracket, the later motor can be swapped in. It's possible to R&I the early motor simply by accessing the door interior. But for the later motor (with Z-bent pushrod), the door latch must also come out.

|

|

|

Early Lock Motor used in trucks until '91

|

|

|

Lock Motor Late.jpg | Hits: 3383 | Size: 26.67 KB | Posted on: 11/27/04 | Link to this image Lock Motor Late.jpg | Hits: 3383 | Size: 26.67 KB | Posted on: 11/27/04 | Link to this image

Late-model door lock motor. 8" when extended; gold mounting bracket & nuts shown are not included, but silver clip & pigtail are.

F-series & Broncos do not use the bridge bracket with 2 nuts; in trucks, the white (silver) lock motor yoke is riveted directly to the door skin.

|

|

|

SOLD Door Lock Motors from '92 F150

Tested working; fit '92-96, & older with slight modification. 8" when extended.

|

|

|

SOLD Window & lock motors

|

|

|

Door Pockets 88.jpg | Hits: 2986 | Size: 50.1 KB | Posted on: 7/26/03 | Link to this image Door Pockets 88.jpg | Hits: 2986 | Size: 50.1 KB | Posted on: 7/26/03 | Link to this image

|

|

|

SOLD Black Threshholds fit '80-96 F-series & Bronco, used on '87-96.

|

|

|

SpeakerGrilleLHF.JPG | Hits: 1962 | Size: 84.67 KB | Posted on: 10/19/07 | Link to this image SpeakerGrilleLHF.JPG | Hits: 1962 | Size: 84.67 KB | Posted on: 10/19/07 | Link to this image

SOLD Mocha LHF speaker grille for '92-96

|

|

|

DoorGlassRyan.JPG | Hits: 2215 | Size: 54.17 KB | Posted on: 10/20/07 | Link to this image DoorGlassRyan.JPG | Hits: 2215 | Size: 54.17 KB | Posted on: 10/20/07 | Link to this image

PRESOLD Door glass & vent windows

|

|

|

SOLD Vent Window Assembly (right) for '92-96 F-series & Broncos; fits '80-96 F-series & Bronco, and '97 F-series over 8500 GVWR.

Pivot is smooth, firm, & quiet; latch lock works; all fasteners included.

Ships as 38x12x8" 8 lbs.

|

|

|

Panels Compared.jpg | Hits: 297 | Size: 70.07 KB | Posted on: 2/27/24 | Link to this image Panels Compared.jpg | Hits: 297 | Size: 70.07 KB | Posted on: 2/27/24 | Link to this image

Unfortunately, there are no new XLT/EB door panels in production anywhere. These are poor copies of the Custom/XL panels with some XLT-ish features molded in. And they're crazy-expensive.

IF THE IMAGE IS TOO SMALL, click it.

|

|

|

DoorPanels96Gy.JPG | Hits: 2267 | Size: 64.72 KB | Posted on: 5/21/09 | Link to this image DoorPanels96Gy.JPG | Hits: 2267 | Size: 64.72 KB | Posted on: 5/21/09 | Link to this image

|

|

|

Weatherbelt Screws

IF THE IMAGE IS TOO SMALL, click it.

If the door panel is broken where the weatherbelt clips go, or to prevent that from happening, screw it to the panel.

.

|

|

|

BroncoLineDoorTest.JPG | Hits: 1594 | Size: 48.07 KB | Posted on: 11/18/12 | Link to this image BroncoLineDoorTest.JPG | Hits: 1594 | Size: 48.07 KB | Posted on: 11/18/12 | Link to this image

I might actually do this...

The goals are to:

- have rain protection while getting in & out (similar to gullwings)

- have a larger opening (UNlike lambos would do)

- open in a standard parking space (UNlike gullwings would do)

- open & close easily & intuitively

- NOT interfere with a pop-up sunroof

- retrofit & align easily & inexpensively

- remove easily for off-roading

- provide at least as much security & safety as the originals

The idea occurred to me back in the 90s, but I haven't developed it much due to lack of a body tub & doors to experiment with, or fabrication equipment, or a work area that large, or time, or money, or...

But since I'm swapping body tubs again, I have the parts. And I bought a nice welder. And I have access to the other stuff. I'm just trying to find the TIME now.

|

|

|

Door inner skin '93EB has louvers near the bottom which are covered by its full door panel.

|

|

|

Door outer skin date stamp '93EB : 6 22 A3

The hole at the Left of the pic (above & rear of the speaker well) is for the flag/paddle-style mirror's inner brace arm bolt. The square hole lower & farther back is for the vent window frame's bolt.

|

|

|

Door inner skin date stamp '93EB : 6 23 7

The rough-edged slot and drilled hole near the bottom Left of the pic are to access the window motor's bolts.

|

|

|

Door speaker screws '93EB horizontal pair: ~5 9/16" OC

There are also 4 non-factory screw holes.

|

|

|

Door speaker well '93EB : ~6 3/8"

The non-factory screw holes are very close to the edge of the speaker well.

|

|

|

Doors made before ~'95 did not have side impact beams.  .  The sprayed material reduces noise & helps stiffen the skin against buckling & whipping at speed.

|

|

|

'93EB door wiring harness boot knockout 2"

|

|

|

'93EB door mirror reinforcement paddle/flag-style

|

|

|