Toying With Turbos: LS1 Remote Mount Turbo System From Squires Turbo Systems

We've seen a lot of things in our day, but a turbo that replaces the muffler? Just the thought seemed silly and impossible. If we hadn't seen it in person we never would have believed it. A black Trans-Am pulled into the Primedia parking lot with an ominous driver and a small STS sticker on the windshield. No thunderous noise, no gaudy hood and no nitrous purge. After a ride around the block we're quite sure that we were in the presence of an honest 10-second street car. So what was the mystery under the hood? We'll give you a clue; it wasn't under the hood at all. The source of the F-bodies' power originated from an STS remote-mounted turbo system blowing into a 383-inch LS1. But how would the system perform on a stock vehicle, we wondered? There was only one way to find out, and we needed a donor vehicle. So, we found a '02 bone-stock SS Camaro to turbo, and boy were we impressed.

STS Turbo Systems has been around for a couple of years, but until recently we had only heard of them as some company in Utah mounting turbos at the back of cars and trucks. It wasn't until we conducted a live installation that we understood how cool the concept of remote mounting a turbo really is. We were under the impression that a turbo system needed a great deal of heat to function, which as we found out was not entirely true. While heat does play a factor in turbo function, it's not the most crucial dynamic. The cone effect, whereby velocity increases inside the turbo housing, is much more vital than the slight heat loss caused by moving the turbo system to the rear of the vehicle.

The engineering behind remote turbo mounting is actually quite simple. By moving the turbo to the back of the vehicle, the need for heat shielding in the engine bay no longer exists. The exhaust gases flow through the manifolds, past the catalytic converter, through the exhaust and into the Garret turbo. The exhaust gas velocity increases about 4,000% inside the turbo housing causing the turbine to spin at 100,000+ RPM. The compressed fresh air is pressurized through HPC coated intake tubes running the length of the chassis, back into the engine bay, directly into the throttle body. While the intake charge must travel the length of the vehicle to reach the motor it is simultaneously being cooled by the ambient air surrounding it, as a result an intercooler is not required. The patented rear-mount turbo/wastegate assembly is designed to hang from the OE exhaust hangers and move with the rest of the exhaust system.

Oiling for the turbo is probably the most beautiful part of the system. The engine's pressurized oil is routed from the oil filter mount through a braided stainless line back to the turbo. The return is pumped back to the engine and is dumped right through the valve cover oil cap. A 12-volt oil pump is installed in-line on the oil return to keep the line scavenging whenever the engine is running. Should any problem occur with the oiling system, an audible alert will sound and the engine can be shut off before any damage occurs to the turbo. Unlike many other forced induction systems, no drilling of the oil pan is necessary for plumbing. While many traditional systems require a turbo timer after running the motor, STS' patented oiling system has much lower oil temperatures making carbonizing of the turbo bearings almost impossible.

On six-speed applications like the install on our '02 SS, a blow-off valve is installed up front just below the MAF sensor. In-between gears, the boost is dumped when the throttle blades shut, keeping the turbo spooled up. On an automatic transmission installation this is not necessary because 'lifting' of the throttle never takes place during a power run.

The STS LS1 system functions at a base level of five pounds of boost, but can be run at seven or eight pounds of boost provided that you purchase the optional methanol injection system. While many of you are familiar with injecting methanol into the intake path you may not be aware of its function. The slight amount of methanol serves two main purposes. First and foremost it supplements the OE fuel system, making the stock injectors satisfactory for an increase in horsepower. Secondly, the Methanol cools the intake charge helping to nullify detonation. For most applications the windshield washer fluid reservoir is converted to a methanol tank, but if the installer is inclined to do so, an additional tank can be installed elsewhere in the rear of the vehicle.

At this point you probably have more questions than answers, as did we when we first learned of remote mount turbocharging. The biggest question on our mind was turbo lag. How is turbo lag avoided with the turbo so far back? According to STS, their systems are designed specially for remote mounting. They use custom sized housings that function awesome in back, but if mounted in the traditional location up front would perform less efficiently. On the flip side, if a traditional front mounted turbo was moved to the rear, lag would become a major issue.

We also wondered, doesn't it take a while to pressurize the intake tube with so many feet of intake tubing? To our surprise, a molecule of air can travel from the turbo to the intake inlet in .05 seconds, which provides boost almost instantaneously. "All the intake tubing adds up to less than half a cubic foot of space," says Rick Squires, owner of STS Turbo Systems.

When we asked Squires about the difference between turbocharging and supercharging he said that, "A centrifugal supercharger impeller works much the same way as a turbocharger. It spins at a high RPM to compress air into the engine. The biggest difference is that while a supercharger is driven directly from the motor, a turbocharger is driven only from exhaust. Due to the correlation between crank RPM and impeller speed a centrifugal blower only makes big boost at high RPM. Conversely, once a turbo starts producing boost, it pulls straight to redline. The higher the RPM the greater the increase in efficency. So, if you desire gobs of torque throughout your useable powerband, go with a turbo."

After receiving the kit from STS we opened the box like a couple of kids on Christmas and went through the parts list to be sure everything was accounted for. We pulled the '02 onto a lift purely to make the photography easier. Starting on the install just after 1:00 pm we had the system installed minus the methanol by 5:00pm. Over the next couple of hours we installed the methanol system, removed the factory ECU and replaced it with the re-flashed turbo-ready ECU from STS.

We rolled up the garage door and fired our turbo wielding F-body for the first time. Keeping in mind that the STS System replaced the factory muffler we were expecting loud obnoxious exhaust notes. To our surprise, the '02 actually idled quieter than stock. As we pulled out into the street with our variable boost controller set to five PSI, we slowly depressed the go pedal and instantly heard the spooling turbo noise we had been yearning for since the day we ordered our system. By the time 3,000 RPM was on the tach we were pinned into the seat with only the thought of a night in jail in the back of our minds. After a few minutes behind the wheel, we flipped the 'OH-BOY' switch to seven PSI, and with the assistance of a little methanol we were incinerating the tires in every gear. It became plainly obvious that a set of drag radials and a long stretch of road were in serious order.

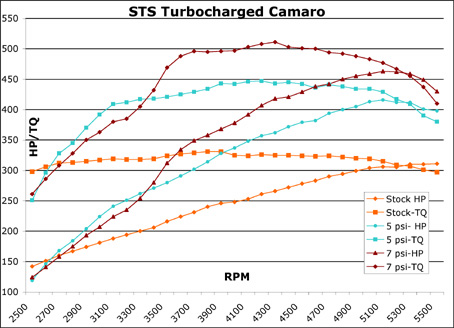

What do we think...we think that you should check out the dyno numbers. We baselined the '02 at L.A. Performance Division for a grand total of 313 rear-wheel horsepower. After installing the system and going back onto the same dyno we produced 463 horsepower and 511 pound feet of torque the very next day. What does this mean to you readers, lots of big, smoky burnouts for about 4,000 bucks!

Installation

The turbo, wastegate and rear plumbing is bench assembled before actual installation.

While one person is assembling the turbo, another can pull the plugs and reset the gap.

The factory air box is removed along with the MAF sensor.

The provided harness can be routed and attached to the OE harness.

The MAF sensor is reinstalled in the provided turbo hose.

The MAF and hose is attached to the first intake tube, which encompasses the blow-off valve.

With the MAF in place, the upper intake tube can be attached to the throttle body.

The OE exhaust can then be removed. Slight cuts may be required on the main exhaust pipe going into the muffler.

The assembled turbo unit can be hung in place at the OE muffler location.

With the turbo in place, the remainder of the intake tubing can be installed and connected with the provided turbo hose.

The oiling system begins with drilling and tapping the small aluminum fitting located next to oil filer. On the Y-body this fitting feeds the oil temperature-sending unit. On a Camaro, this fitting is blocked off.

The stainless oil pressure line is run straight to the turbo.

After the oil goes through the turbo, a 12-volt pump returns the used oil back to the passenger valve cover.

To keep particulate out of the intake path, a K&N Filtercharger¨ is installed at the mouth of the intake.

The methanol injector is installed in the inlet tube. Be sure to use plenty of TeflonĒtape.

Source

STS Turbo Systems

165 N. 1330 W., Suite C4

Orem, UT 84057

866-WE-TURBO

www.ststurbo.com

L.A. Performance Division

10155 Canoga Ave.

Chatsworth, CA 91311

877-THE-LAPD

www.thelapd.com

Back to the article index.