|

|

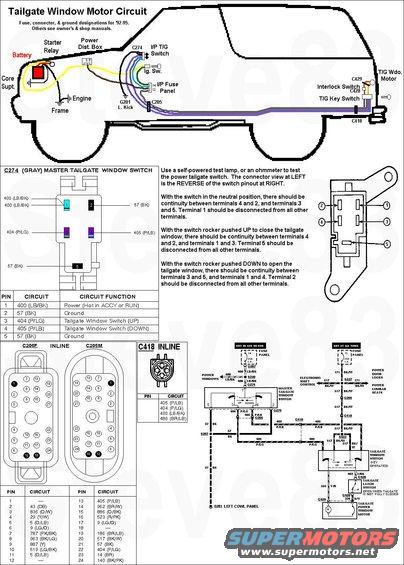

TGMotorWiring.JPG | Hits: 28769 | Size: 61.24 KB | Posted on: 12/4/08 | Link to this image TGMotorWiring.JPG | Hits: 28769 | Size: 61.24 KB | Posted on: 12/4/08 | Link to this image

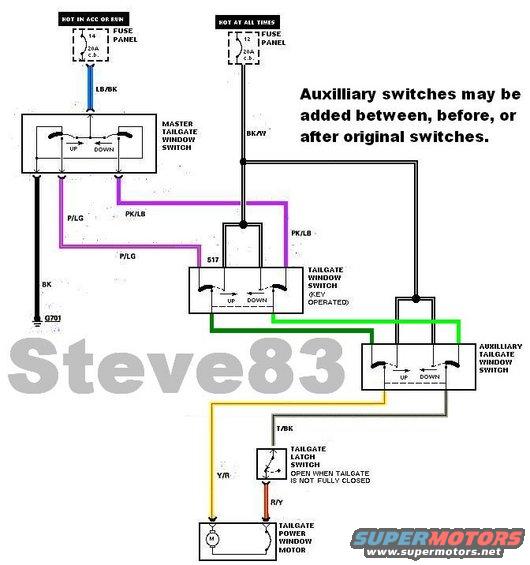

Tailgate Motor Wiring '92-95 (other years similar) IF THE IMAGE IS TOO SMALL, click it. The 2 Purple wires & Bk/Wh between C205 (firewall) & C418 (rear frame) are in the frame harness.  .  .  All '80-96 t/g wiring runs from the dash switch (F2TZ-14529-A Motorcraft SW7071 ~$25~65) out the firewall along the frame to the rear bumper up to the L taillight and into the t/g. '80-86 have a large round 3-wire connector in the LHR taillight well; those with rear defrost also have a 1-wire connector. All years with rear defrost have a ground ring screwed to the body in the taillight well. I think '87-91 have the large round connector in front of the taillight AND a smaller round 4-wire connector inside the frame at the LHR body mount. '92-96 only have the frame connector. Normal operation is as follows: RAISE from the dash switch: Power ( 12VDC) flows thru fuse 14 thru the LB/BK wire thru the IP switch UP contacts thru the P/LG wire thru the key switch UP contacts thru the Y/R wire to the motor brushes, commutator, & windings; then it grounds thru the motor's internal CB, out thru the R/Y wire thru the latch switch thru the T/Bk wire thru the key switch DOWN contacts thru the Pk/LB wire thru the IP switch DOWN contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos). LOWER from the dash switch: Power flows thru fuse 14 thru the LB/BK wire thru the IP switch DOWN contacts thru the Pk/LB wire thru the key switch DOWN contacts thru the T/Bk wire thru the latch switch thru the R/Y wire thru the motor's internal CB to the motor brushes, commutator, & windings; then it grounds out thru the Y/R wire thru the key switch UP contacts thru the P/LG wire thru the IP switch UP contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos). RAISE from the key switch: Power flows thru fuse 12 thru the BK/Wh wire thru the key switch thru the UP contacts thru the Y/R wire to the motor brushes, commutator, & windings; then it grounds thru the motor's internal CB out thru the R/Y wire thru the latch switch thru the T/Bk wire thru the key switch DOWN contacts thru the Pk/LB wire thru the IP switch DOWN contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos). LOWER from the key switch: Power flows thru fuse 12 thru the BK/Wh wire thru the key switch DOWN contacts thru the T/Bk wire thru the latch switch thru the R/Y wire thru the motor's internal CB to the motor brushes, commutator, & windings; then it grounds out thru the Y/R wire thru the key switch UP contacts thru the P/LG wire thru the IP switch UP contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos). Note that in ALL cases, EVERY terminal & contact of EVERY switch is used, and the circuit ALWAYS grounds at the same point. To eliminate/bypass the dash switch, unplug it & install 2 jumpers as described in the "neutral position" within the diagram. If that text isn't legible, click the pic to supersize it. The following diagram shows how to semipermanently bypass either switch, as well as some other modifications.  To add a simple self-diagnostic capability, wire a 12V lamp (incandescent - NOT LED) across the safety switch terminals, and mount it in the tailgate shell above the lock cylinder in the inside sill (through a carpet retainer hole if present). If either control switch is activated, and the only thing preventing the glass from moving is the safety switch, the lamp will light and be visible to a person using either switch.  .  For C418, see:  .  C429 is WPT-484 C418 is WPT-386(427)/171(756) C274 is WPT-653 '78-91 use a 3-blade connector (WPT-601/706) for the motor wiring behind the L taillight. See also:  .  .  .  .  .  .  .  .  .  .

|

|

|

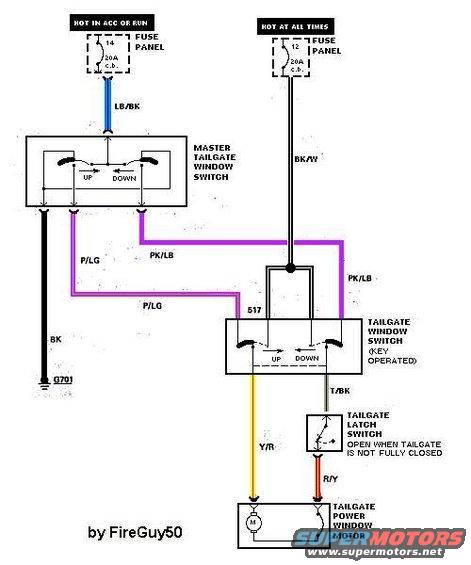

Tailgate Window Circuits IF THE IMAGE IS TOO SMALL, click it. . See also:  .  .  .  .  .  .  .  .  .  .  .

|

|

|

Tailgate Window Circuit.jpg | Hits: 13564 | Size: 33.93 KB | Posted on: 11/29/04 | Link to this image Tailgate Window Circuit.jpg | Hits: 13564 | Size: 33.93 KB | Posted on: 11/29/04 | Link to this image

Window Motor Circuit from http://www.fordfuelinjection.com/Note that the internal circuitry for the master switch is specific to '78-86 Broncos, and the most-common base color for the wires between the switches is PURPLE; not pink (the base color for door lock circuits). See also:  .  Normal operation is as follows: RAISE from the dash switch: Power flows thru fuse 14 thru the LB/BK wire thru the IP switch UP contacts thru the P/LG wire thru the key switch UP contacts thru the Y/R wire to the motor; then it grounds thru the motor's internal CB, out thru the R/Y wire thru the latch switch thru the T/Bk wire thru the key switch DOWN contacts thru the Pk/LB wire thru the IP switch DOWN contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos). LOWER from the dash switch: Power flows thru fuse 14 thru the LB/BK wire thru the IP switch DOWN contacts thru the Pk/LB wire thru the key switch DOWN contacts thru the T/Bk wire thru the latch switch thru the R/Y wire thru the motor's internal CB to the motor; then it grounds out thru the Y/R wire thru the key switch UP contacts thru the P/LG wire thru the IP switch UP contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos). RAISE from the key switch: Power flows thru fuse 12 thru the BK/Wh wire thru the key switch thru the UP contacts thru the Y/R wire to the motor; then it grounds thru the motor's internal CB out thru the R/Y wire thru the latch switch thru the T/Bk wire thru the key switch DOWN contacts thru the Pk/LB wire thru the IP switch DOWN contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos). LOWER from the key switch: Power flows thru fuse 12 thru the BK/Wh wire thru the key switch DOWN contacts thru the T/Bk wire thru the latch switch thru the R/Y wire thru the motor's internal CB to the motor; then it grounds out thru the Y/R wire thru the key switch UP contacts thru the P/LG wire thru the IP switch UP contacts to the Bk wire to the ground in the kick panel (or dash on older Broncos). Note that in ALL cases, EVERY switch is used, and the circuit ALWAYS grounds at the same point. To add a simple self-diagnostic capability, wire a 12V lamp across the latch safety switch terminals, and mount it in the tailgate shell above the lock cylinder in the inside sill (through a carpet retainer hole if present). If either control switch is activated, and the only thing preventing the glass from moving is the safety switch, the lamp will light and be visible to a person using either switch.

|

|

|

The Bronco tailgate window circuit is a common (Ford) polarity-reversing circuit with 2 switches. Each switch has its own power feed; the dash switch through the ignition switch (key-on only) and the tailgate key switch from the battery (always hot). The dash switch normally holds both motor wires to ground, and the key switch normally holds the motor wires to the dash switch wires. When either is operated, it sends one of the wires hot, powering the motor (assuming the latch switch is closed). When operated the other way, the polarity is reversed, reversing the motor's direction. Neither switch is a "master" because neither will work if the other is disconnected OR in the opposite position. To add a simple self-diagnostic capability, wire a 12V lamp across the latch safety switch terminals, and mount it in the tailgate shell above the lock cylinder in the inside sill (through a carpet retainer hole if present). If either control switch is activated, and the only thing preventing the glass from moving is the safety switch, the lamp will light and be visible to a person using either switch.  .  See also:

|

|

|

Tailgate Switch Wiring Colors

These wires are not intended to be removed from the switches, and the switches are not intended to be removed from the mounting plates, so the t/g internal switch is essentially a part of the t/g wiring harness assembly.

When using the key to LIFT the glass, the Pu/LB wire provides ground thru the dash switch. When LOWERING, the Pu/LG wire provides ground.

To replace one or both, drill out the rivets and either cut the wires or break open the damaged switch to unhook them from it. Then mount the replacement switch & connect the wires. Bk/Wh goes to the COMmon terminal; the Pu/? wire goes to the NC terminal; the other (motor wire) to the NO terminal.

|

|

|

Tailgate Key Switches IF THE IMAGE IS TOO SMALL, click it. These switches are not removable or repairable. This one was broken. See also:  .  .  .  .  .  .  .  .  .  .  .  .

|

|

|

'92-96 Dash Switch F2TZ-14529-A & Motorcraft SW7071 costs ~$25~65 if you can find it.

IF THE IMAGE IS TOO SMALL, click it.

Imported knock-offs are available, and these genuine switches are probably out of production.

|

|

|

Dash Switch Testing IF THE IMAGE IS TOO SMALL, click it. This is a new cheap copy, and it works. See also:  .  .  .  .  .  .  .  .  .  .  .

|

|

|

'78-96 Bronco Tailgate Wiring Installation IF THE IMAGE IS TOO SMALL, click it. 1 - Switch and Housing Assembly (Includes 14086 Wiring) - 14046 2- Latch Assembly - 43170 3 - Ground ring terminal to Heated Backlight only 4 - Screw - 55927-S2 5- Cylinder Case Assembly - 7143184 6- Remote Control Assembly - 9843170 8 - Locator (Part of 14086 Wiring Assembly) 9 - Guard Channel (Part of 14086 Wiring Assembly) 10 - Locator (Part of 9844000 Window Regulator Assembly) 11 - Wiring (Part of 9844000 Window Regulator Assembly) 12 - Existing Locator Bracket (Part of Door Assembly) 13 - To Window Limit Switch 14 - Wiring (Part of 14046 Switch and Housing Assembly) 15 - Strap - 95873-S 16 - Limit Switch Assembly - 14A011 A. Circuit 57: Black B. Circuit 186: Brown-Light Blue Stripe See also:  .  .  .  .  .  .  .  .  .  .  .  .  .

|

|

|

'92-96 Bronco Tailgate Wire Harness Routing IF THE IMAGE IS TOO SMALL, click it. 1 - Wiring Assembly (Standard Production) 13A409 2 - Locator, Position in Hole Provided (Part of 14086) 3 - Screw N805375-S36MG 4 - Wiring Assembly (Tailgate) 14086 5 - Frame Assembly 5005 6 - Wiring Assembly 14405 7 - To Tailgate Assembly 8 - Locator (Shown in Installed Position) (Part of 13A409) 9 - Tailgate Assembly 40700 10 - To Backup Lamp 11 - Clip 377105-5 12 - To Turn Signal and Stoplamp 13 - Interconnect (14405) 13A409 14 - Cap 14A099 See also:  .  .  .  .  .  .  .  .  .  .  .

|

|

|

Pinout for '87-96 Dash Switch CONNECTOR (harness side) for Tailgate Window (Looking into the switch, the pins would be reversed.) IF THE IMAGE IS TOO SMALL, click it. Pin 2 is normally closed to pin 4, & pin 3 to pin 5. When the switch is operated, either pin 3 or pin 4 is momentarily opened from ground & closed to pin 1 (power). To bypass the dash switch & test the rest of the circuit for DOWN, turn the key to RUN or ACC, install a jumper (paperclip, etc.) from 3 (P/LG) to either ground (2 or 5 Bk), then install a jumper from 1 to 4. To test UP, jumper 4 to either ground, and 3 to 1. If the motor doesn't spin during both tests, the dash switch is NOT the only fault. Maximum current draw when glass is moving is 4A @ 14VDC. See also:  .  .  .  .  .  .  .  .  .  .  .

|

|

|

'87-91 Tailgate Switches IF THE IMAGE IS TOO SMALL, click it. . See also:  .

|

|

|

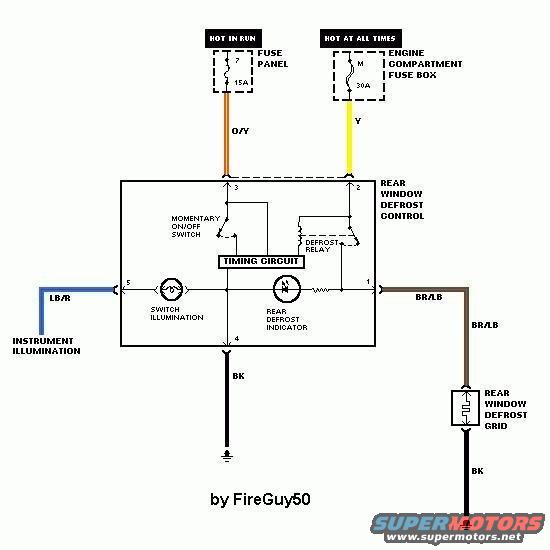

Defroster Circuit '92-96 IF THE IMAGE IS TOO SMALL, click it. . See also:  .  .  .  .  .  .  .  .  .  .  .

|

|

|

Tailgate Defrost Circuit.jpg | Hits: 6170 | Size: 27.24 KB | Posted on: 11/29/04 | Link to this image Tailgate Defrost Circuit.jpg | Hits: 6170 | Size: 27.24 KB | Posted on: 11/29/04 | Link to this image

|

|

|

SOLD '80-96 Bronco Tailgate Glass (w/o defrost E0TZ9842006B, w/defrost F2TZ9842006A) Defrost grid is damaged in at least 8 places, so this can be considered an UNheated window. Actual dimensions: 60x22x2" 17.5 lbs Shipping dimensions: 64x26x2" 22 lbs For a writeup on installation & alignment, read this: http://www.fourdoorbronco.com/board/showthread.php?t=5224

|

|

|

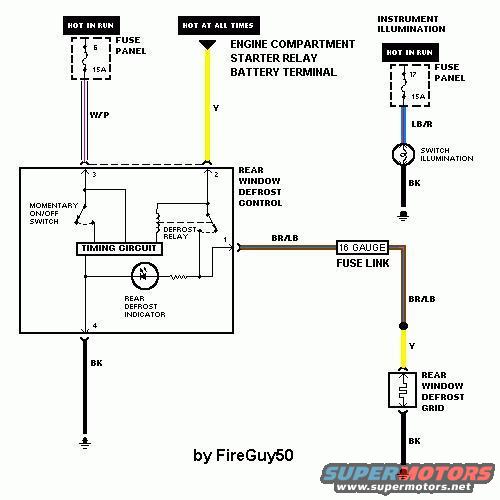

Tailgate Defrost Circuit Early.jpg | Hits: 6149 | Size: 29.67 KB | Posted on: 11/29/04 | Link to this image Tailgate Defrost Circuit Early.jpg | Hits: 6149 | Size: 29.67 KB | Posted on: 11/29/04 | Link to this image

|

|

|

Note that there is no connector near the ground wire, which is forward of the L taillight. C418 is located inboard of the L frame rail between the rear bumper & the gas tank rear crossmember. Earlier Broncos ('78~91) have a bulky 3-pin connector for the window motor near G400 (the ground is only used with the optional defroster). They also have a single-pin connector for power to the optional defroster. Very early FSBs ('78~86) don't have this style of C418 or any connector in its location - the t/g frame harness is continuous from the firewall up to the taillight.

|

|

|

This is all the wiring for the tailgate, except the ground for the defrost grid. This connector is located inboard of the L frame rail between the rear bumper & the gas tank rear crossmember.

|

|

|

Tailgate Connector '87-91 IF THE IMAGE IS TOO SMALL, click it. . See also:  .  .  .  .  .  .  .  .  .  .  .

|

|

|

Tailgate Connector Comparison IF THE IMAGE IS TOO SMALL, click it. . See also:  .  .  .  .  .  .  .  .  .  .  .

|

|

|

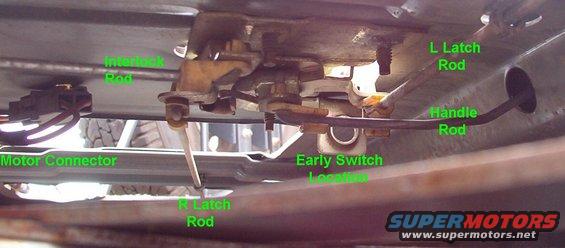

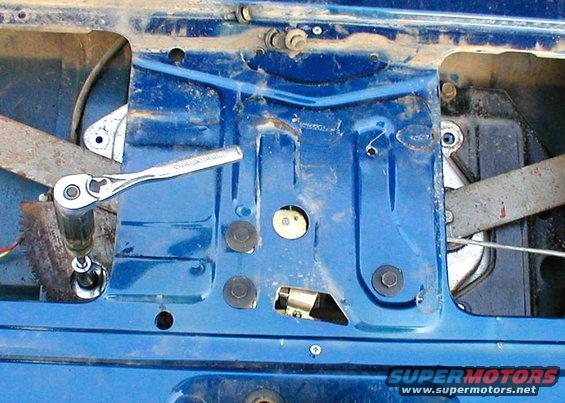

To access the motor connector, push out these 2 retainers and pull the connector where you can see it. If you're only changing the motor drive gear, this isn't necessary.

|

|

|

The L latch must be fully closed to defeat the safety interlock switch so the motor will run, so if neither switch works, try hitting the L side of the t/g with your shoulder to fully close the latch.

If the window can't be moved by either switch, find the motor connector shown on the drill chuck and apply 12V power to the 2 exposed wires to operate the motor. Reversing the wires reverses the motor direction. Position the glass so that the track nuts are just above the lower edge of the opening. This glass is too high.

If the tailgate is closed, reach behind the center divider and pull the operating rod down to enable the latch, and open the tailgate. (See later pics.)

|

|

|

Window Motor Terminals IF THE IMAGE IS TOO SMALL, click it. After scratching the wire colors into the plastic shell, release the terminals for cleaning. Female terminalSee also:  .  .  .  .  .  .  .  .  .  .  .  .

|

|

|

Terminals Tinned.jpg | Hits: 0 | Size: 68.98 KB | Posted on: 11/13/25 | Link to this image Terminals Tinned.jpg | Hits: 0 | Size: 68.98 KB | Posted on: 11/13/25 | Link to this image

Tinned Terminals IF THE IMAGE IS TOO SMALL, click it. The corrosion on these was bad enough to sandblast them, then dip them in a crucible of molten electrical solder. See also:  .  .  .  .  .  .  .  .  .  .  .

|

|

|

'92-96 Bronco Tailgate Connector Location

IF THE IMAGE IS TOO SMALL, click it.

See also:

.

|

|

|

tailgate-window-circuit-aux.JPG | Hits: 6759 | Size: 43.25 KB | Posted on: 11/15/06 | Link to this image tailgate-window-circuit-aux.JPG | Hits: 6759 | Size: 43.25 KB | Posted on: 11/15/06 | Link to this image

Auxilliary t/g window switch circuit for '78-86 Broncos. This design is fairly simple, but requires long splice wires (due to the factory routing), and creates extra resistance in an already-stressed circuit. For a VASTLY superior modification to '87-96 Broncos, see:  Note that the internal circuitry for the dash switch is specific to '78-86 Broncos. To add a simple self-diagnostic capability, wire a 12V lamp across the latch safety switch terminals, and mount it in the tailgate shell above the lock cylinder in the inside sill (through a carpet retainer hole if present). If either control switch is activated, and the only thing preventing the glass from moving is the safety switch, the lamp will light and be visible to a person using either switch.

|

|

|

Tailgate Window Circuit Modifications IF THE IMAGE IS TOO SMALL, click it. '92-96 shown; '87-91 similar; NONE OF THESE control switch improvements (left 2 columns) will work for '78-86 Broncos due to the internal wiring of the dash switch. The simplifications, indicator lamp, & 1-touch WILL work on '78-96.  The factory circuit passes full current through 4 terminals of BOTH switches every time the window is used, resulting in high resistance & slow window movement. The modified circuits: - reduce the current passing through the switches (making them last longer); - replace the special switches with 2 common relays (making them easier to replace if they ever go bad); - allows any number of additional switches with no degredation in performance; - uses the factory wiring & circuit breakers, and requires NO new wires through the tailgate hinge (for most trucks). If the truck doesn't have a factory defrost ground wire, then one heavy ground must be added from the body inside the L taillight well to the tailgate relays & switch. The Improved (Ground-Switched) Circuit has the benefits of converting to always-on, and having no hot wires strung through the truck. This is the best way to add switches &/or improve t/g window function. Note that there are no modifications to the frame harness. The Hot-Switched circuit has the benefit of being simpler to rewire. But the grounds MUST be removed from the dash switch connector, and a fused hot wire must be strung to each new switch location. The Loaded Circuit adds 1-touch modules & an indicator light to the ground-switched circuit, but both of those mods will work equally well on the hot-switched circuit, or the stock circuit.  The Simplified circuits reduce the motor to a single control switch, but do NOT protect the window from accidental breakage by raising the t/g after raising the glass. The indicator lamp is not required in the One-Touch circuit, but it's a simple & useful addition to ANY circuit with a functional latch safety switch, including those where the indicator lamp is not shown. An easy lamp to use is RadioShack 272-0332. Any lamp used in this application must light in either polarity, like an incandescent bulb or a double-polarity LED.  Making the dash switch (& door windows) work at all times is another HIGHLY-functional mod.  But if the 1-touch modules catch rain with the always-on mod, they will short; lowering the windows &/or draining the battery. See also:

|

|

|

Loaded '92-96 Bronco Tailgate Harness IF THE IMAGE IS TOO SMALL, click it. Many worthwhile improvements can be easily integrated into the tailgate harness, without modifying the frame or dash harnesses. See also:

|

|

|

Dash Switch Rewire

IF THE IMAGE IS TOO SMALL, click it.

When installing relays in the t/g to unload the switches, the dash switch must be re-pinned as simple NO (normally-open) grounds.

|

|

|

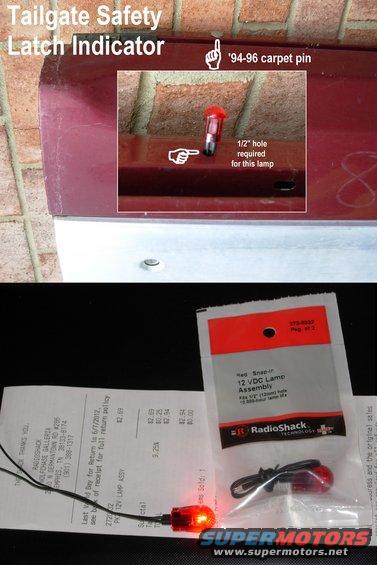

LatchIndicator.JPG | Hits: 8769 | Size: 48.95 KB | Posted on: 5/20/12 | Link to this image LatchIndicator.JPG | Hits: 8769 | Size: 48.95 KB | Posted on: 5/20/12 | Link to this image

Bronco Tailgate Safety Latch Light  .  This can be any common 12V incandescent panel lamp. It's simply wired across the safety switch Motorcraft SW5163 in a '78-96 Bronco tailgate. If the window doesn't work, and the lamp lights, the problem is that the safety switch isn't closed, probably due to the the tailgate latches not being fully closed, and the tailgate should be re-aligned. If the lamp DOESN'T light when the window won't move, the fault is elsewhere.  An LED should NOT be used because it will only work for one window direction (either up or down).

|

|

|

Tailgate Latch Light indicates that the latch is not fully closed when attempting to operate t/g window motor. IF THE IMAGE IS TOO SMALL, click it.  .  This can be any common 12V incandescent panel lamp. It's simply wired across the safety switch Motorcraft SW5163 in a '78-96 Bronco tailgate. If the window doesn't work, and the lamp lights, the problem is that the safety switch isn't closed, probably due to the the tailgate latches not being fully closed, and the tailgate should be re-aligned. If the lamp DOESN'T light when the window won't move, the fault is elsewhere.  An LED should NOT be used because it will only work for one window direction (either up or down).

|

|

|

These aftermarket belts fit perfectly, and my original end seals are still in useable condition.

The red light is my own modification to indicate when the t/g isn't fully latched.

|

|

|

'94-96 Tailgate w/o Carpet Unused carpet holes plugged with pushpins, indicating all '94-96 tailgates have carpet holes.  .  To add a simple self-diagnostic capability, wire a 12V lamp across the safety switch terminals, and mount it in the tailgate shell above the lock cylinder in the inside sill (through a carpet retainer hole if present). If either control switch is activated, and the only thing preventing the glass from moving is the safety switch, the lamp will light and be visible to a person using either switch. If the glass doesn't move AND the lamp doesn't light, the fault is elsewhere.

|

|

|

Pushpins (14 required)

IF THE IMAGE IS TOO SMALL, click it.

Tailgate carpet uses the same pushpins as camper trim.

|

|

|

Tailgate Carpet ('94-96 only) IF THE IMAGE IS TOO SMALL, click it. These t/g carpet pushpins have coarser fins than the originals for the camper trim, but are interchangeable. Head Dia.: 19/32" Stem Dia.: 9/32" Stem Lgth.: 27/32" AuVeCo #.........Color 19371 ...............Blue (lapis) 19372 ...............Dark Gray (granite) 19373 ...............Light Gray (opal) 19374 ...............Tan (mocha)  To add a simple self-diagnostic capability, wire a 12V lamp across the safety switch terminals, and mount it in the tailgate shell above the lock cylinder in the inside sill (through a carpet retainer hole if present). If either control switch is activated, and the only thing preventing the glass from moving is the safety switch, the lamp will light and be visible to a person using either switch.  See also:  .

|

|

|

Tailgate Carpet Cutouts

IF THE IMAGE IS TOO SMALL, click it.

Most reproduction carpets are not cut for the handle, lack holes for the pushpins, and aren't even cut squarely along the edges.

|

|

|

TGCarpet93Mocha.JPG | Hits: 3245 | Size: 104.15 KB | Posted on: 3/23/11 | Link to this image TGCarpet93Mocha.JPG | Hits: 3245 | Size: 104.15 KB | Posted on: 3/23/11 | Link to this image

SOLD Mocha Tailgate Carpet

Pushpins included

|

|

|

SOLD Bronco Tailgate Carpet

'94 Royal Blue fits '78-96 tailgates. Some mounting pushpins included.

Actual dimensions: 5 lbs 61x20x2"

|

|

|

TailgateCarpetMocha.JPG | Hits: 6346 | Size: 58.94 KB | Posted on: 4/7/06 | Link to this image TailgateCarpetMocha.JPG | Hits: 6346 | Size: 58.94 KB | Posted on: 4/7/06 | Link to this image

SOLD Tailgate Carpet NEEDS CLEANING

Ships as 5 lbs 62x21x3". I could roll it to try to reduce the shipping cost, but I don't recommend it. It has a rigid molded backing.

|

|

|

If the motor spins but won't move the glass (F2TZ9842006A), just push it down all the way, and you can open the tailgate. Never try to open or close the t/g with the glass sticking up as shown. It should be FULLY inside the t/g. If the glass is broken, or if the glass is down but the handle still won't work, see this:

|

|

|

Tailgate Window Mechanisms IF THE IMAGE IS TOO SMALL, click it. The outside weatherbelt that wipes the glass (w/o defrost E0TZ9842006B, w/defrost F2TZ9842006A) is D8TZ-9841610-A and cost $24 in 1996. The inner (9841676 above) is F6TZ-9842072-AA and was $27. Use silicone spray lube on the flocked weatherbelts & glass runs. The slides & tracks ON THE GLASS should be kept clean & dry because the plastic slides are their own lubricant. But if you must use grease, the best grease for them would be PTFE:  Graphite paint in the channels is even better because it dries. Reassemble in this order: 1. pressure wash & allow to dry in sun for a day or 3 2. undercoat inside bottom (to prevent rust) & allow to dry for a day or 3 3. lock cylinder, latches, center mechanism, inside handle, bottom bumpstops, regulator w/motor 4. switch & harness, outside trim panel (if applicable) 5. side tracks 6. glass (F2TZ9842006A) 7. glass tracks, weatherbelts 8. end seals, rain shield 9. access panel

|

|

|

If you only need to change the weatherbelts, or if the glass (F2TZ9842006A) needs to come out, remove the screw from each end seal and rotate them up toward the glass to disengage the hooked end from the lip inside the window opening. Then remove the screw at each end of the outer weatherbelt.

To install, hook the end seal under the inside lip, slide it toward the end, rotate it down under the exterior lip, and slide it back in so its screw can be installed.

|

|

|

AFTER removing the screw at each end, use a screwdriver to gently pry the OUTER weatherbelt up just enough to pop the cllps loose. I've pulled the far end out to show the clips, but it should be left straight until ALL the clips are loose, then lifted out without bending. The inner seal is removed the same way (it has no screws), but use a rag between the screwdriver and the paint.

The outside weatherbelt is D8TZ-9841610-A (interchange FO1930103) and cost $24 in 1996. The inner is F6TZ-9842072-AA (interchange FO1930104) and was $27.

2014 prices

Supplier . . . . Inner Belt . . . . . . . . . . . . Outer Belt . . . . . . . . . . . . Camper Run

RockAuto . . . F2028 $18 . . . . . . . . . . . F2027 $18 . . . . . . . . . . . F1019 $43

LMC . . . . . . . 49-9466 $30 . . . . . . . . . 49-9465 $40 . . . . . . . . . . 49-9461 $40 not sure

JBG . . . . . . . . pair 34543 $55 pair of inner & outer . . . . . 36020 $39 NOT CORRECT

|

|

|

SOLD Tailgate Outer Weatherbelts (D8TZ9841610A) These are the belts that wipe the outside of the rear glass on '78-96 Bronco tailgates. The rubber is still pliable, & all the flocking and clips are still present. There is one tiny cut less than 1/2" long that I barely noticed. For a writeup on installation & alignment, read this: http://www.fourdoorbronco.com/board/showthread.php?t=5224

|

|

|

These aftermarket weatherbelts are shipped as a pair (as they should be) and are virtually identical to the originals, including holes & installed clips.

|

|

|

I apply dry (Teflon) lube to the flocked surfaces that touch the glass, and silicone spray to the other rubber surfaces. The dry lube prevents noise & abrasion, and allows the glass to move faster; and the silicone helps preserve the rubber & reduce water deposits, ozone damage, and general aging.

|

|

|

Perfect matches. The outer belt (D8TZ9841610A, E8TZ9841610A, F20207) is longer than the inner (F6TZ9842072AA, F2028 ).

Pair: KF2027, W0116-G761736

|

|

|

Weatherbelts.JPG | Hits: 10002 | Size: 31.64 KB | Posted on: 11/28/04 | Link to this image Weatherbelts.JPG | Hits: 10002 | Size: 31.64 KB | Posted on: 11/28/04 | Link to this image

This outer weatherbelt has begun to dry rot, and is already leaking water into the unpainted interior of the tailgate. The dirt it brings with it will cause the bottom of the tailgate to rust out from the inside. If the inner one gets this bad, it will scratch the heating element which could cause a hot spot that would shatter the glass.

|

|

|

The wetness on the moisture barrier shows that the weatherbelts are dry-rotted & should be replaced before they scratch the heater grid or glass. They're also allowing dirt that accumulates on the glass to fall or wash into the t/g, causing rust.

|

|

|

One of several signs that the t/g weatherbelts are ruined is rain coming out of the access panel and soaking the rear carpet. This can be difficult to notice if the ('94-96 only) t/g carpet is installed, but the trails are visible here. They appear because the factory painted paper water shedder is installed in the easy (WRONG) location, and it deteriorates rapidly.

Other signs of weatherbelt failure include:

- defrost grid abrasions, sometimes causing the glass to shatter when the defroster is activated

- glass abrasions

- loose glass

- noise when glass is moving

- tailgate rust

|

|

|

The factory drip shield is just painted paper with duct tape along the bottom (which has never made sense to me), and it's almost useless. I'm surprised this one is in such good condition. It's taped along the bottom (the t/g is upside-down), and has a tacky adhesive along the top and across the middle. But since the rain leaks in along the top where the weatherbelt meets the glass, and then drips off the bottom edge of the glass, it falls on the paper and then runs in between the paper the t/g. The tape is supposed to create a seal & a dam that holds the rain in its pocket, forcing it to flow back into the t/g, but over the years, the rain works its way down past the tape. Then it flows down between the t/g & the access panel, out onto the t/g threshold seal. When that fills, it overflows the threshold and runs over to the carpet, where it seeps in and continues forward (assuming the truck is parked flat) under the rear seat, and down onto the front floor where it soaks into THAT carpet. Eventually, it makes its way to the front door thresholds where it corrodes the wiring.

|

|

|

This is a factory water shedder. It's taped along the bottom (the t/g is upside-down), and has a tacky adhesive along the top and across the middle. But since the rain leaks in along the top where the weatherbelt meets the glass, and then drips off the bottom edge of the glass, it falls on the paper and then runs in between the paper the t/g. The tape is supposed to create a seal & a dam that holds the rain in its pocket, forcing it to flow back into the t/g, but over the years, the rain works its way down past the tape. Then it flows down between the t/g & the access panel, out onto the t/g threshold seal. When that fills, it overflows the threshold and runs over to the carpet, where it seeps in and continues forward (assuming the truck is parked flat) under the rear seat, and down onto the front floor where it soaks into THAT carpet. Eventually, it makes its way to the front door thresholds where it corrodes the wiring.

|

|

|

The inner face of the water shedder is painted black so it doesn't absorb water QUITE as fast as if it was bare.

I've never understood why Ford didn't use a plastic shedder here, like on the front doors; OR why it was installed so that the water still comes inside the t/g.

|

|

|

This can be done with the tailgate open or closed. After removing the inside access panel, remove the vapor barrier. This one had 2, but it was obviously accidental.

|

|

|

If the motor runs but doesn't move the glass (w/o defrost E0TZ9842006B, w/defrost F2TZ9842006A), push the glass up for access. The glass is strong enough to support its own weight fully extended, but not much extra weight. If the motor doesn't run, remove the 4 nuts (2 on each side - see below) that hold the regulator tracks to the glass brackets. Bend the regulator arms down slightly to pull the studs out of the brackets, and then push the glass up or down as needed. Remember to FULLY lower or remove the glass before lifting or closing the t/g.  .  .

|

|

|

Tailgate Watershield IF THE IMAGE IS TOO SMALL, click it. The factory painted-paper shield is ineffective & installed wrong. This one actually sheds water toward the drains instead of inside the cargo area. This scrap of common plastic drop sheet should last much longer than the factory paper water shedder, and perform much better installed inside the t/g where it can actually work. Being very careful not to wrinkle the plastic, I applied a few strips of Gorilla tape along the top edge, folded the bottom over so it would fit through the access hole, and fed it straight into the t/g along the glass. This was the REALLY tricky part: lifting the tape and sticking it to the t/g inner reinforcement bar, without wrinkling the plastic. But this location will cause any water dripping off the bottom of the raised glass to fall on the glass side of the plastic. Then it will run down the plastic past the access opening and out the bottom of the t/g thru its original drain holes, onto the ground where it belongs. After the tape is secure along the top, the plastic sheet is unfolded and tucked so it SHOULD stay between the glass and the operating rods. The driver's side has to stay clear of the defrost wiring (if installed). The tape is stuck to the "inner top reinforcement" in this photo:  I don't expect it to be very difficult to push the plastic out of the way for t/g service, but time will tell. If it has to come out, it's cheap, and quick to replace.

|

|

|

This is the optimum location for the glass since you have access to all the fasteners to remove the regulator in this position. The other side is similar. To hit this spot, watch thru the glass (green pointer at lower R) for the hole in the gear to line up with the regulator mounting bolt. Glass rivet isolator

|

|

|

The nuts for the glass track (red pointers) are under this fixed support, but the bolts for the regulator (green pointers) will be accessible after the glass is removed.

|

|

|

The R nuts are covered by the structure, so a ratcheting boxend is the easiest tool to get at them. Alternatively, this hole could be enlarged and another drilled above the other nut for socket access.

|

|

|

Probably the most-common damage to a Bronco t/g: backing into a stationary object. Trees just don't move fast enough to get out of my way.

|

|

|

Most people are paranoid about breaking the glass (w/o defrost E0TZ9842006B, w/defrost F2TZ9842006A) if it's fully extended with the t/g down, but I do this all the time, and I've never broken one. I even use it as a VERY-LIGHT-DUTY work table. I don't jump on it, but that 12V impact weighs a few pounds, and it's fine. If your t/g is already split along the R side, don't do this. It won't hurt the glass, but it will do more damage to the t/g skin. For more info, see the Right Side Split album..  .

|

|

|

The 3 black bolts hold the center latch mechanism (remote control) and are used to align it so the handle lies flat, and the latches open at the same time.

But at this age, it's usually not enough. The remote control is usually damaged by someone jerking the handle up when the glass isn't all the way down, bending the remote. To fix it, it usually has to be removed & straightened or replaced. See the NEXT several pages...

|

|

|

If the glass is clear of the shell, but you can't open the t/g, remove the inside access panel & pull the 2 rods inward (the L rod is obscured behind the tailgate, but it runs to the L Rod Clip). Either unclip them from the center mechanism, or pull them like bow strings to release each latch. Make sure the glass isnt so high that it engages the camper shell's groove, or it could break. If it wont come down, unbolt the regulator slides from the glass, or the motor from the regulator to lower the glass.

|

|

|

Mark the bolt locations for reference, even if you plan to move the center mechanism later.

|

|

|

Mechanism In.JPG | Hits: 10431 | Size: 29.95 KB | Posted on: 11/28/04 | Link to this image Mechanism In.JPG | Hits: 10431 | Size: 29.95 KB | Posted on: 11/28/04 | Link to this image

View from the driver's side  .

|

|

|

Mechanism Side.JPG | Hits: 9764 | Size: 55.57 KB | Posted on: 11/28/04 | Link to this image Mechanism Side.JPG | Hits: 9764 | Size: 55.57 KB | Posted on: 11/28/04 | Link to this image

View from the passenger side  .

|

|

|

To release the rods, push the hook end of the plastic clip off the rod so the plastic pivots in the rod hole, then pull the rod down out of the clip. Note the bent lever in the center. This is what happens when someone attempts to open the t/g before the glass is fully down. It results in the inside handle standing up, and the t/g being hard to open even with the glass all the way down.  CONTINUE TO THE NEXT SEVERAL PAGES...

|

|

|

Center mechanism front & back. Ford calls it the "remote control".

The rubber grommet for the handle operating rod is slid onto that lever just for storage.

The interlock rod (top & bottom) hangs under the glass. The black retainer keeps it from rattling or swinging out-of-place.

|

|

|

Center Mechanism.JPG | Hits: 9538 | Size: 54.24 KB | Posted on: 11/28/04 | Link to this image Center Mechanism.JPG | Hits: 9538 | Size: 54.24 KB | Posted on: 11/28/04 | Link to this image

The center mechanism (remote control)

|

|

|

The white plastic rod clips indicate the direction of each rod. Top of tailgate is top of photo. Left of photo is passenger (right) side of t/g.

|

|

|

Center Interlock.JPG | Hits: 9378 | Size: 60.26 KB | Posted on: 11/28/04 | Link to this image Center Interlock.JPG | Hits: 9378 | Size: 60.26 KB | Posted on: 11/28/04 | Link to this image

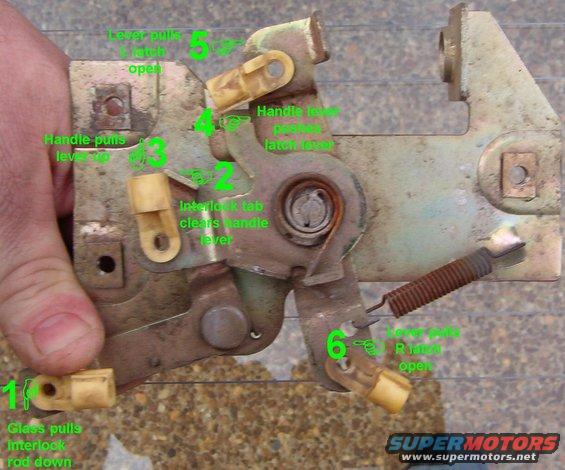

The numbers show the sequence of events for PROPER operation of the inside latch handle. 5 & 6 should be simultaneous, and the long rods can be bent to take up any slack & get the latches to open at the same moment. But do so only AFTER aligning the tailgate.

|

|

|

This is why the inside handle doesn't sit flat. If someone pulls the handle before the glass is fully down (disengaging the interlock), then the handle lever bends. Rod clip

|

|

|

I've never found a used tailgate whose remote was NOT bent, but this is among the worst.

|

|

|

Remote Repair

IF THE IMAGE IS TOO SMALL, click it.

After removing the removable springs, clamp the remote's center rivet between sockets in a vise so that the handle arm can be straightened using channel locks & an adjustable wrench.

|

|

|

Remote Repair

IF THE IMAGE IS TOO SMALL, click it.

The top row is before (BENT); the bottom row is the same views after the lever has been straightened.

|

|

|

Center Straight.JPG | Hits: 8507 | Size: 25.77 KB | Posted on: 11/28/04 | Link to this image Center Straight.JPG | Hits: 8507 | Size: 25.77 KB | Posted on: 11/28/04 | Link to this image

Fortunately, with the mechanism out, it's easy to straighten the bent lever. Spray it with WD-40 or flowable grease before re-installing it. If the center (top) lever doesn't rotate freely enough for the coil spring to return it, the latches can't lock.

|

|

|

Latch & Switch.JPG | Hits: 11325 | Size: 68.04 KB | Posted on: 11/28/04 | Link to this image Latch & Switch.JPG | Hits: 11325 | Size: 68.04 KB | Posted on: 11/28/04 | Link to this image

This is the safety interlock switch Motorcraft SW5163 (possibly also Standard SLS66) on the driver's latch that prevents the motor from operating with the tailgate open. Ford put it here from ~'85 until '96. Before that, it was on the center mechanism and was sensitive to EITHER latch being open. To add a simple self-diagnostic capability, wire a 12V lamp across the safety switch terminals, and mount it in the tailgate shell above the lock cylinder in the inside sill (through a carpet retainer hole if present). If either control switch is activated, and the only thing preventing the glass from moving is the safety switch, the lamp will light and be visible to a person using either switch.  To permanently defeat it (and risk breaking the t/g glass), unplug its connector & install a jumper wire between the 2 terminals.

|

|

|

Mechanism Inside.JPG | Hits: 13238 | Size: 82.57 KB | Posted on: 7/7/03 | Link to this image Mechanism Inside.JPG | Hits: 13238 | Size: 82.57 KB | Posted on: 7/7/03 | Link to this image

The rod running to the Left (down) is the interlock rod that detects the glass being fully down. It is supported by a clip similar to the ones used for the hood cable, and the ones visible here on the long latch rods. The one to the R (up) is the one from the inside handle. You can see that the mechanism it's attached to is bent. This comes from attempting to open the tailgate before the glass is FULLY down and it causes the inside handle not to return fully flat.  .

|

|

|

White Interior

IF THE IMAGE IS TOO SMALL, click it.

Regardless of the external color, the t/g interior should always be white so it's easy to see what's happening inside it.

|

|

|

Safety Interlock Switch IF THE IMAGE IS TOO SMALL, click it. Contrary to popular belief, this switch virtually NEVER fails, and a glance inside shows why: it's too simple. See also:  .  .  .  .  .  .  .  .  .  .  .

|

|

|

Interrupt Switch Testing

IF THE IMAGE IS TOO SMALL, click it.

When the plunger is released (latch closed), the circuit should be closed (0 resistance). When depressed, the circuit is open (infinite resistance, out-of-range, OUCH).

|

|

|

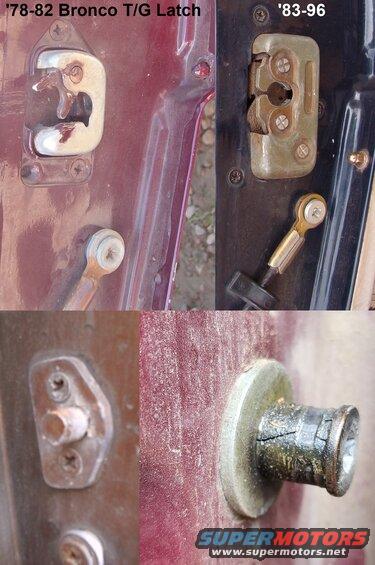

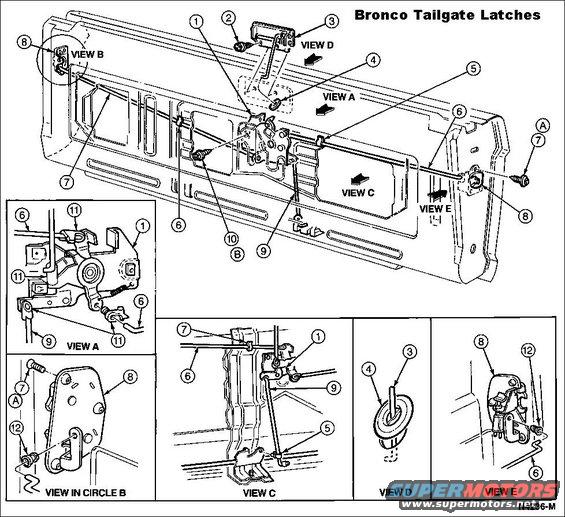

'78-82 Bronco Tailgate Latches

IF THE IMAGE IS TOO SMALL, click it.

.

|

|

|

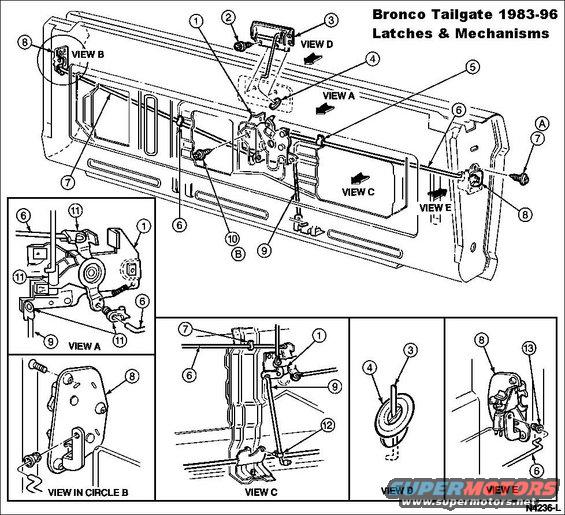

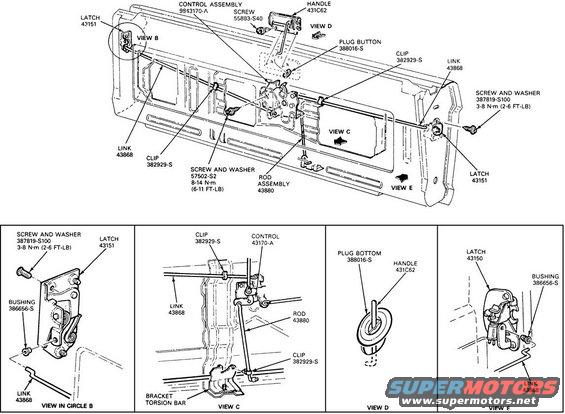

'83-96 Bronco Tailgate Latches

IF THE IMAGE IS TOO SMALL, click it.

.

|

|

|

Mechanism All.JPG | Hits: 9925 | Size: 73.53 KB | Posted on: 11/28/04 | Link to this image Mechanism All.JPG | Hits: 9925 | Size: 73.53 KB | Posted on: 11/28/04 | Link to this image

This shows the interlock switch Motorcraft SW5163 (possibly also Standard SLS66) installed in its early location on the center mechanism ONLY for illustration.

|

|

|

Tailgate (or Door) Latch Cleaning

IF THE IMAGE IS TOO SMALL, click it.

Latches that have not been properly maintained may need deep cleaning to restore proper operation. Soak in solvent (naphtha, kerosene, or deodorized mineral spirits - NOT gas or diesel) until the old caked grease is soft enough to scrub out using tooth/bore brushes. When dry, wash in warm soapy water to remove any remaining mud, and dry thoroughly (sunlight for a few hours, or a heat gun for a few minutes). Then apply a flowable grease sparingly to the internal mechanisms while operating the jaws & release repeatedly. The upper jaw of the left latch may not fully open without assistance due to the follower for the safety switch, but this is normal and NOT a problem to be fixed. When installed & aligned, the strike bolt opens that jaw fully.

|

|

|

Latch Restoration

IF THE IMAGE IS TOO SMALL, click it.

Nearly identical to the original coating.

|

|

|

Latch Closed.JPG | Hits: 10377 | Size: 35.98 KB | Posted on: 11/28/04 | Link to this image Latch Closed.JPG | Hits: 10377 | Size: 35.98 KB | Posted on: 11/28/04 | Link to this image

To operate the motor with the tailgate open, simply close the driver's latch. Be SURE to open it before you attempt to close the tailgate or you'll damage the plastic sleeve on the strike bolt. On '78~85, BOTH latches must be closed because the interlock switch is mounted to the center mechanism. Installation & removal of the latches is also easier when they're closed.

|

|

|

Latch Rods Adj Bend92 e.jpg | Hits: 0 | Size: 99.77 KB | Posted on: 11/13/25 | Link to this image Latch Rods Adj Bend92 e.jpg | Hits: 0 | Size: 99.77 KB | Posted on: 11/13/25 | Link to this image

Latch Operating Rod Adjustment

IF THE IMAGE IS TOO SMALL, click it.

To take up the slack so that the latches open as soon as the handle is barely lifted, simply bend the rods. The slack is NOT due to the rods stretching (which can't happen), but because of wear inside the latches.

|

|

|

Regulator Remove.JPG | Hits: 7518 | Size: 82.08 KB | Posted on: 11/29/04 | Link to this image Regulator Remove.JPG | Hits: 7518 | Size: 82.08 KB | Posted on: 11/29/04 | Link to this image

With the regulator arms in this position (note the socket on the bolt in the regulator gear hole), all the mounting bolts can be accessed & removed.

But this regulator position DOES load the lift spring, so do NOT remove the motor from the regulator with the arms NOT attached to the glass AND in any position other than fully UP against the stop. If the arms are still attached to the glass, the motor can be removed with the arms in any position.

|

|

|

Regulator Out.JPG | Hits: 7163 | Size: 68.47 KB | Posted on: 11/29/04 | Link to this image Regulator Out.JPG | Hits: 7163 | Size: 68.47 KB | Posted on: 11/29/04 | Link to this image

The regulator fits out the driver's side. On earlier Broncos, there is a brace here that must be removed. It has 1 phillips screw at the bottom. The slot for its top tab is visible in the foreground.

|

|

|

These motor screws aren't very tight in the threads, so I'm threadlocking them in. Since this motor is so new & works so well, I doubt the truck will last long enough for it to need replacement again.

|

|

|

'78-96 Bronco Tailgate Window Regulator front & back (early regulator arms may have round swivels instead of square) Motor wires are 35", with a retainer 12" from the motor, a molded rubber 90° bend at 20", another retainer 1/2" past that, and the 3rd retainer around 32" If EITHER the glass or the motor is installed, the regulator is safe. But if BOTH are removed with the arms down, the lift spring will snap both arms up violently, which could cause injury. The regulator must be in THIS position (nearly fully down) to remove it from the tailgate, but if the motor has to be removed, power it so the arms go to the full up position first. When the L arm is barely touching the stop, it's safe to remove the motor. Actual dimensions w/motor: 11.5 lbs 24x16x3" Actual dimensions w/o motor: 8.5 lbs 24x16x1.5" The best grease for the slides & tracks is PTFE.  .

|

|

|

RegulatorTGSpring.jpg | Hits: 0 | Size: 81.5 KB | Posted on: 11/13/25 | Link to this image RegulatorTGSpring.jpg | Hits: 0 | Size: 81.5 KB | Posted on: 11/13/25 | Link to this image

Regulator Spring

IF THE IMAGE IS TOO SMALL, click it.

To clean the regulator, use vise-grips to unload & remove the spring.

|

|

|

Regulator Import.jpg | Hits: 0 | Size: 62.42 KB | Posted on: 11/13/25 | Link to this image Regulator Import.jpg | Hits: 0 | Size: 62.42 KB | Posted on: 11/13/25 | Link to this image

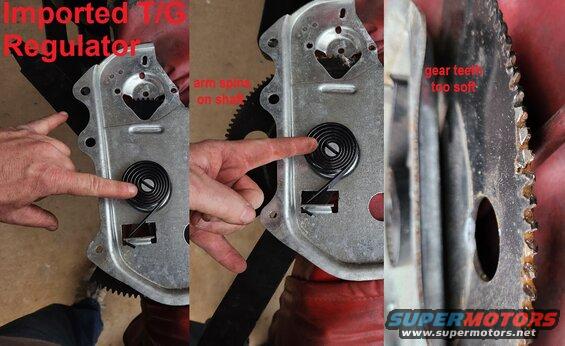

New Tailgate Regulator

IF THE IMAGE IS TOO SMALL, click it.

They're all garbage. Simply clean the original regulators because they virtually never need replacement.

|

|

|

To access the motor, remove these 3 bolts (5/16" or 8mm 6-point head w/integral washer; 12-24x5/8"). If the glass has already been removed, the regulator's spring can snap the arms & gears, so be careful.

It's MUCH easier to remove the regulator first.

|

|

|

Wire Unclipped.JPG | Hits: 8107 | Size: 36.81 KB | Posted on: 11/29/04 | Link to this image Wire Unclipped.JPG | Hits: 8107 | Size: 36.81 KB | Posted on: 11/29/04 | Link to this image

To get enough slack in the wire to pull the motor out & work on it, remove the clip from the bottom of the tailgate. Remember to reinstall it later, or the wire could become entangled in the glass or regulator.

That hook on the L side is the bottom of the interlock rod, but it's disconnected at the top & laid over to the side right now. Normally, its long section would point straight at that hole in the background.

|

|

|

When the glass (F2TZ9842006A) can be moved by hand, it usually means the motor's drive bushings have degraded to powder or mush. In this particular case, though, I found the motor loose in the t/g. I assume someone changed it, but couldn't get the screws started, and gave up. In another rare case, the plastic outer gear shattered, allowing the bushings to roll around the drive gear's triangular hub.

|

|

|

If the window doesn't move while the motor is turning, it's likely that the bushings inside the motor gear have disintegrated. To change or repair the motor drive gear, remove the phillips screw and then the seal plate to expose the gear. Never fill the case with grease - it's unnecessary, messy, and probably causes more problems than it could prevent. Also see:  .  GO TO THE NEXT few pages...

|

|

|

Window Motor Gear.jpg | Hits: 10190 | Size: 48.91 KB | Posted on: 11/29/04 | Link to this image Window Motor Gear.jpg | Hits: 10190 | Size: 48.91 KB | Posted on: 11/29/04 | Link to this image

This is the repair kit (DOAZ-62234A24-B $27.37 List; $20.53 in 2004), but you can also use 1/4" fuel hose with thin plastic tubing inside to reinforce it & cut to length, or even appropriately-sized nuts to fill in where the original rubber insulators were. There are also aftermarket suppliers of the Delrin bushings visible inside the gear assembly, and they cost ~$5 for the kit. See p.35 of this PDF: https://www.henrysautomotivewarehouse.com/2017_web.pdfAlso see:  GO TO THE NEXT page...

|

|

|

The pointers show what's left of the rubber insulators, which probably degraded faster due to the excessive grease inside the gear. As the new part demonstrates, NONE is required inside the white plastic gear. The metal & nylon gears simply slide up off the shaft. The kit includes grease to lube the central shaft & the outer teeth of the new gear before installation. Reattach the seal plate, & reinstall the motor on the regulator. Push or pull the glass slightly to align the gears so the motor mounting holes will line up. Lube the regulator gears while you have access. There's also an aftermarket repair kit available from any parts store that deals in MotorMite HELP! parts - it's just the 3 delrin bushings (green pointer), and you stuff them into your gears. Advance charges ~$8 for them, which is a rip-off price. See p.35 of this PDF: https://www.henrysautomotivewarehouse.com/2017_web.pdfMany people just drop 3 steel nuts in; they'll never wear out. You can also use sections of coil spring cut to length, thick rubber hose with something inside to keep it from collapsing, or even just fill the gears with epoxy. Also see:  Motor bolts are 5/16" (8mm) 6-point head w/integral washer; 12-24x5/8".

|

|

|

There are several stock motors that will fit & work, and this might be the fastest one I've found. I have no idea what it came out of, though.

|

|

|

The motor drive's shaft aligns thru the hole in the top of the regulator. If the large gear is popping off the motor gear, bend the small tab down that overhangs the regulator gear to hold it flat against the regulator chassis. Also, ensure that the motor is mounted properly to the back of the regulator.

|

|

|

Regulator Channels

IF THE IMAGE IS TOO SMALL, click it.

Grease collects grime, causing wear & binding. Either keep the channels & slides clean & dry (the plastic is its own lubricant), or apply graphite paint (which dries).

|

|

|

Bronco Tailgate Emergency Access Templates

These allow 4 holes to be drilled in the tailgate inner skin for access to the glass channel nuts when the glass is fully down AND the motor is dead, or seized, or the regulator is mechanically locked. Once the nuts are removed, the glass can be raised and the motor or regulator repaired.

But it's stupid to drill into the t/g. Remove the inside access panel (#2 Phillips x10), and reach inside to get the four 7/16" (11mm) nuts off the glass regulator tracks. It might be tight to get the wrench on & the nuts off, but it's better than having holes in the t/g.

|

|

|

Swingaway Brace.JPG | Hits: 8033 | Size: 71.44 KB | Posted on: 11/29/04 | Link to this image Swingaway Brace.JPG | Hits: 8033 | Size: 71.44 KB | Posted on: 11/29/04 | Link to this image

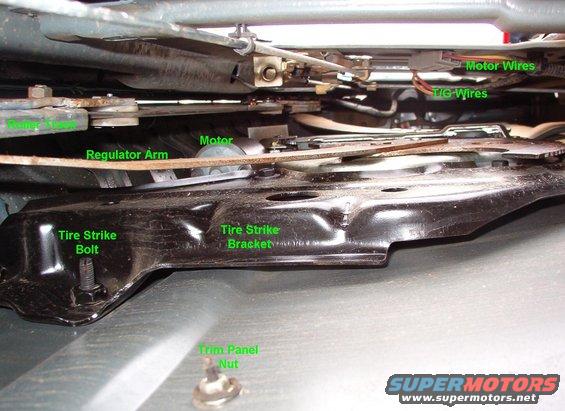

Before removing the regluator, remove the tire carrier's strike brace (if equipped).

|

|

|

Strike Bracket.JPG | Hits: 7939 | Size: 67.45 KB | Posted on: 11/29/04 | Link to this image Strike Bracket.JPG | Hits: 7939 | Size: 67.45 KB | Posted on: 11/29/04 | Link to this image

Later Broncos (~'90-96) have 3 bolts holding the strike to the bracket. Before that, there were only 2.

|

|

|

Tailgate Trim 86EFI.jpg | Hits: 5036 | Size: 14.61 KB | Posted on: 7/12/03 | Link to this image Tailgate Trim 86EFI.jpg | Hits: 5036 | Size: 14.61 KB | Posted on: 7/12/03 | Link to this image

|

|

|

The trim panel can be removed after the access panel if the glass is rolled up out of the way. No other disassembly is needed. On '78-86, remove the 4 black phillips screws from the corners of the trim panel on its rear (outer) face. On '87-91, remove the 2 gold stamped nuts (9mm) from each inner side of the tailgate. On '92-96, remove the 2 closed nuts (11mm) from each inner side of the tailgate. On all, remove the 2 gold stamped nuts (9mm) inside the tailgate on each side of the regulator. Later panels have foam rubber around the outer edge that may adhere to the paint.

|

|

|

SOLD Tailgate Trim Panel from '95 Bronco (F2TZ-98425A34-A) Fits '78-96; includes all original fasteners. Blue oval has been replaced, those nuts have been removed, and the pegs are clipped flush. The smoke stripe is reflecting the eaves of my house - there are no significant blemishes on it, and it's still shiny. Ships as 68x16x6" @ 14lbs. For a writeup on installation & alignment, read this: http://www.fourdoorbronco.com/board/showthread.php?t=5224Black strip (only) w/oval & fasteners F2TZ-98425A34-BKP ~$175 sh tax

|

|

|

SOLD '83-96 Bronco Tailgate from '96 Black EB, with '92-96 trim panel (F2TZ-98425A34-A) Inside latch handle doesn't lie flat. Trim panel smoke stripe has a white drip (possibly paint). Carpet needs cleaning. NO RUST, dents, cracks, or noticeable damage - just scuffs on the paint & normal wear. Includes '92-96 wiring harness to frame, heated glass, carpet, access panel, hinges, swingaway strike, all original hardware. For a writeup on installation & alignment, read this: http://www.fourdoorbronco.com/board/showthread.php?t=5224Actual dimensions: 70x24x7" 129 lbs Shipping dimensions: 70x 27x9" 170 lbs MUST GO TRUCK FREIGHT or be picked up locally if left complete. For cheaper shipping, I can remove the regulator w/motor, and ship it separately.

|

|

|

'87-96 Trim Panel Hole Layout IF THE IMAGE IS TOO SMALL, click it. Double-check against your trim panel's fastener locations before drilling. Carpet pin locations should be marked through the carpet's holes, after the carpet is aligned to the handle & centered on the t/g. Swingaway strike holes should be aligned to the interior structure and brace.  .

|

|

|

TailgateLockParts.JPG | Hits: 9820 | Size: 38.01 KB | Posted on: 7/7/06 | Link to this image TailgateLockParts.JPG | Hits: 9820 | Size: 38.01 KB | Posted on: 7/7/06 | Link to this image

Lock Cylinder for '78-96 Bronco tailgate https://www.npdlink.com/product/lock-cylinder-and-keys-tailgate/207568/80870The parts are shown in factory order: E-ring Spacer Spring washer Paddle Flat washer Extension Hairpin Lock Cylinder The switch assembly (permanently attached to the t/g wiring harness) fits around the extension in the insets. TSB 99-24-02 Service PN: F6TZ-9821984-AA I usually keep spare lock cylinders, so if you can't find one locally, e-mail me thru my profile here. As of 7/18, I have 8 with keys & 1 without.  SEE THE NEXT SEVERAL PICS...

|

|

|

This can be used as a pattern to bend a replacement clip from an appropriate wire, like the spring for a C-cell battery. just be sure to set the print resolution at 600dpi, or increase the white background size (in pixels) to 600x the print area in inches.

|

|

|

New Lock Cylinder

IF THE IMAGE IS TOO SMALL, click it.

This repro is virtually perfect.

|

|

|

The tailgate key switch is 2 weather-resistant SPDT micro switches riveted into a bracket, and operated by a paddle attached to the lock cylinder. The lock cylinder is retained by the brown clip against the painted surface, much like the door lock cylinder retainer clips. The switch assembly is retained on the lock cylinder by the hairpin behind the center of the paddle. I usually keep spare lock cylinders, so if you can't find one locally, e-mail me thru my profile here.  .

|

|

|

When the key is rotated CW, the paddle presses the lower switch. The silver hairpin clip retains the switch assembly on the lock cylinder. I usually keep spare lock cylinders, so if you can't find one locally, e-mail me thru my profile here.  .

|

|

|

When the key is rotated CCW, the paddle presses the upper switch. Note the arrangement of parts on top of the switch bracket: E-ring, spacer, spring washer, paddle, switch bracket. I usually keep spare lock cylinders, so if you can't find one locally, e-mail me thru my profile here.  .

|

|

|

By removing ONLY the silver clip, the switch assembly can be removed from the lock cylinder. I usually keep spare lock cylinders, so if you can't find one locally, e-mail me thru my profile here.  .

|

|

|

Swingaway Pad

IF THE IMAGE IS TOO SMALL, click it.

This pad is used to protect the tailgate paint from the rubber bumper on the bottom of the swingaway tire carrier. The pad is adhesive, and the pins keep it from sliding when the truck bounces. Applying teflon dry lube (TDL) or silicone grease will prevent the rubber bumper from stretching the pad like this. If it has come off, the best replacement I've found is UHMWPE tape.

.

|

|

|

This pad is used to protect the tailgate paint from the rubber bumper on the bottom of the swingaway tire carrier. The pad is adhesive, and the pins keep it from sliding when the truck bounces. Applying teflon dry lube (TDL) or silicone grease will prevent the rubber bumper from stretching the pad like this. If it has come off, the best replacement I've found is UHMWPE tape.  .

|

|

|

Swingaway Bump Pad IF THE IMAGE IS TOO SMALL, click it. Rather than drilling holes in a replacement tailgate to keep the original pad in-place, UHMWPE or PTFE tape doesn't have enough friction to the rubber to be pushed. And it's nearly clear, so it can go over any color, including a tape stripe. Keeping the rubber bumper CLEAN, and applying silicone grease/ spray or dry PTFE spray to the rubber will also keep it from pushing the pad.  .

|

|

|

To remove these clips (which are used on the frame also), push the pin in the center all the way through.

|

|

|

With the center pin out, the clip compresses, and can be pulled out of its hole.

|

|

|

Tailgate cables.JPG | Hits: 6502 | Size: 59.56 KB | Posted on: 11/29/04 | Link to this image Tailgate cables.JPG | Hits: 6502 | Size: 59.56 KB | Posted on: 11/29/04 | Link to this image

Early cable screws are #3 or #4 phillips; later ones are T-50. New cables are available from most parts stores for ~$13ea. I may have some for sale. E-mail me thru my profile.

|

|

|

Torsion Bar '78-82 IF THE IMAGE IS TOO SMALL, click it. Loop bolt 57472S40

|

|

|

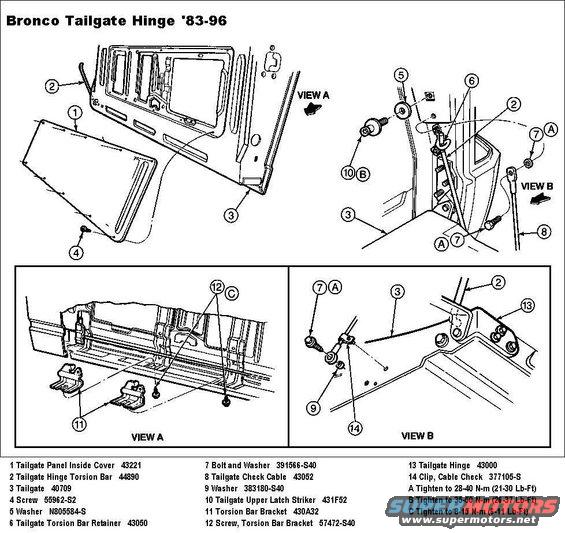

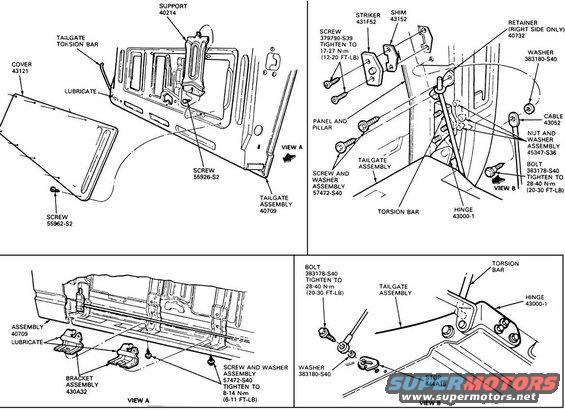

Torsion Bar '83-96 IF THE IMAGE IS TOO SMALL, click it. 1 - Tailgate Panel Inside Cover 43221 2 - Luggage Compartment Door/Tailgate Hinge Torsion Bar 44890 3 - Tailgate 40709 4 - Screw #2Ph. drive #8x3/4", Tailgate Panel Inside Cover-to-Tailgate 55962-S2 5 - Washer N805584-S 6 - Tailgate Counterbalance Torsion Bar Body Retainer 43050 7 - Shoulder Bolt and Washer, Check Cable-to-Body 391566-S40 8 - Tailgate Check Cable 43052 9 - Washer 383180-S40 10 - Tailgate Upper Latch Striker 431F52 11 - Torsion Bar Bracket 430A32 12 - Screw 7/16" hex 14-20 thread captive fender washer, Torsion Bar Bracket 57472-S40 13 - Tailgate Hinge 43000 14 - Clip, Cable Check 377105-S A - Tighten to 28-40 N-m (21-30 Lb-Ft) B - Tighten to 35-50 N-m (26-37 Lb-Ft) C - Tighten to 8-15 N-m (6-11 Lb-Ft) Loop bolt 57472S40

|

|

|

TGTorqueRodBrkt.JPG | Hits: 5756 | Size: 58.28 KB | Posted on: 9/12/07 | Link to this image TGTorqueRodBrkt.JPG | Hits: 5756 | Size: 58.28 KB | Posted on: 9/12/07 | Link to this image

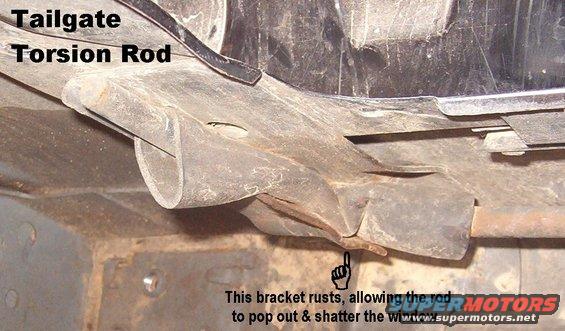

The infamous torsion bar bracket. It cups up, so if it's allowed to collect dirt & rain, it rusts out. Then, when the t/g is lowered, the torque on the rod breaks the bracket, and the bottom corner of the bar (with the foam tube) swings down & shatters the window.

|

|

|

With the R hinge fully back, the torsion bar will BARELY fit out. Raising the hinge, or raising the t/g on the lower hinge, would help. The foam sleeve has to come off the inside end before it will slide out of the hole, and there are 2 clamp brackets (430A32, available from Dennis Carpenter as 98430A30) bolted to the bottom that must be removed.

|

|

|

TGTorqueRodRemv.JPG | Hits: 6797 | Size: 60.75 KB | Posted on: 9/12/07 | Link to this image TGTorqueRodRemv.JPG | Hits: 6797 | Size: 60.75 KB | Posted on: 9/12/07 | Link to this image

Torsion Bar Removal & Installation The tailgate must be misaligned or removed to get the torsion bar in or out. The foam sleeve also has to come off the inside end for the rod to come out of the hole, and there are 2 clamp brackets (430A32, available from Dennis Carpenter as 98430A30) bolted to the bottom that must be removed.  For a writeup on installation & alignment, read this:

|

|

|

Tailgate Reinforcement Plates

IF THE IMAGE IS TOO SMALL, click it.

|

|

|

Strike Nut

IF THE IMAGE IS TOO SMALL, click it.

Like the door strike bolts, the tailgate strikes use a captive nut in the body that's easy to remove. If it falls out, simply re-install it. The fingers that hold it can be bent tighter so it doesn't fall out as easily.

|

|

|

Latch Difference.jpg | Hits: 0 | Size: 51.46 KB | Posted on: 11/13/25 | Link to this image Latch Difference.jpg | Hits: 0 | Size: 51.46 KB | Posted on: 11/13/25 | Link to this image

Latch & Strike Comparison

IF THE IMAGE IS TOO SMALL, click it.

This is why '78-82 tailgate shells are not interchangeable with '83-96s.

|

|

|

'78-82 tailgate latches are significantly different from '83-96. Because they mount differently in the tailgate, neither the latches nor the t/g skins will interchange across those years. This is the only significant difference on '78-96 Bronco tailgates.  Their strikes that mount to the body can be interchanged with some effort.

|

|

|

StrikeBolt 78Bronco.jpg | Hits: 7531 | Size: 56.08 KB | Posted on: 11/29/04 | Link to this image StrikeBolt 78Bronco.jpg | Hits: 7531 | Size: 56.08 KB | Posted on: 11/29/04 | Link to this image

'78-82 Broncos used this type of strike bolt, and a different latch from '83-96. They are not interchangeable.  .

|

|

|

This is an '83-96 tailgate strike bolt installed in the hole for a '78-82 type using a large angle-iron nut plate (not visible inside). Although not ideal, it has worked fine for ~12 years of rough use. I suspect the reason it's holding up is that I keep the t/g aligned, so there's very little stress on the strikes. It's barely visible here:

|

|

|

Strike Bolt Position

IF THE IMAGE IS TOO SMALL, click it.

After the t/g is aligned on its hinges to the body, the strike bolts must be aligned so they meet the centers of the latches by watching through the gaps while slowly closing the t/g.

|

|

|

'83-96 Bronco Tailgate in cross-sectional views '78-82 is only different in the latches & interlock switch takeout, which comes off the motor harness near the center mechanism. For latch details, see this:  .  .  The wiring harness is slightly different behind the taillight: early trucks have a large 3-blade connector for the window motor, and optionally a 1-blade for the defrost; later trucks' harnesses continue to a 4-pin connector inside the frame rail forward of the bumper. All with defrost have a ring terminal behind the taillight (G400).

|

|

|

Exploded Tailgate IF THE IMAGE IS TOO SMALL, click it.

|

|

|

Gordon tailgate shells are made in Taiwan, and I think they're the only company making them right now, regardless of the seller.

IF THE IMAGE IS TOO SMALL, click it.

.

|

|

|